Tabletop CO2 Extractor

& Small CO2 Extraction Machine

Supercritical CO2 Extraction Machine

CO2 Essential/CBD Oil Extraction Equipment for sale at factory price

What is

Supercritical CO2 Extraction Machine?

A Supercritical CO2 Extraction Machine is a device that uses carbon dioxide in its supercritical state (high pressure and temperature) to extract compounds from various materials such as plants, herbs, and food products.

Over 30+ years, BIT has supplied thousands of Supercritical CO2 Extraction Equipment to numerous corporate and university laboratories around the world. Supercritical CO2 Extraction Machine is named CO2 Extraction Machine, CO2 Extractor, CO2 Extraction Equipment, CBD Oil CO2 Extraction Machine, CO2 extraction System, CO2 Oil Extractor, and CO2 Essential Oil Extraction Equipment.

- High flow rates, and high extraction efficiency;

- Scalability: Variety of extraction methods and different amounts of material, from small batches to large quantities;

- Refines extract during the primary extraction while maintaining efficiency, fast speeds, high throughput, and quality;

- Safe CO2 extraction: multi-point pressure monitoring, overpressure protection, emergency stop, and pressure relief valves;

- Extraction made easy: easy-to-use interface, user-friendly, standard with a touchscreen interface to control data logging, temperature, and pressure control;

- All housed ASME 304 or 316 structural grade stainless steel, GMP ready;

- Low energy consumption: reduce operating costs and minimize environmental impact;

- Easy maintenance: easy to clean and maintain to ensure consistent and reliable performance over time.

Types of

Supercritical CO2 Extraction Machine

BIT design, production, and sale of 4 oz Tabletop CO2 Extractor to 1lb Small CO2 Extraction Machine up to 3000lb Industry CBD Oil CO2 Extraction Machines and CO2 Essential Oil Extraction Equipment at very competitive prices.

BIT’s CO2 Extraction Equipment is available in a range of sizes and capacities to meet the processing requirements of different applications: Includes small-scale operations and research(home), medium-scale processing, and industry-grade CO2 extraction machines; with capacities ranging from 4 oz up to 3000 lb for production of essential oil/CBD oil and other extracts.

- Extraction pressure: 35MPa up to 105MPa;

- Tabletop CO2 Extractor: 100 – 200 mL;

- Small CO2 Extraction Machine: 0.5 – 5 L;

- CBD Oil CO2 Extraction Machine/CO2 Essential Oil Extraction Equipment: 10 L up to 9000 L.

The supercritical fluid fractionation column (SFF) with the corresponding capacity can be customized.

Tabletop CO2 Extractor & Small CO2 Extraction Machine For Sale

BIT Top Sellers 4 oz to 2 lb Small CO2 Extraction Machines Including Tabletop CO2 Extractors. Prices and Cost: From $16,700.00/ Set. 1.0 Sets(Min. Order);

Pressure up to 105MPa, 4 oz – 5000 mL CNC Automatic Small CO2 Extraction Machine. Prices and Cost: From $16,700.00/ Set. 1.0 Sets(Min. Order);

Video of Small CO2 Extraction Machine

BIT can provide a 100 – 6000 ml laboratory small CO2 extraction machine with different specifications for feasibility study, small sample preparation, rapid supercritical CO2 extraction process screening, high degree of automation, complete system configuration, and wide design parameters.

The small CO2 extraction Machine can be used for colleges and universities, research institutes, food processing plants, pharmaceutical units, etc. to do supercritical small-scale scientific research experiments and small-scale production of various materials and various CO2 extraction processes.

L-06 Small CO2 Extraction Machine

Classic Small CO2 Extraction Machine Recommended: 6000mL small CO2 extraction machine is a multi-purpose small-batch CO2 extractor, which has two extractors with different capacities (1000mL+5000mL).

It means that it can work in the extraction capacity of 1L or 5L (5L CO2 extraction vessel can hold 1 pound to 3 pounds of dry biomass material per batch.), which is very important for the work of the laboratory because you can use it to carry out small experiments under the capacity of 1L, and then enlarge the test results to 5L capacity for testing, Prove that the extraction data is reliable, and prepare for large-scale commercial or industrial production.

At the same time, we have equipped it with high pressure of 500 bar. Of course, you can also order a higher gas pressure of 1050 bar to meet a wider range of plant extraction requirements.

Why do you need an L-06?

Supercritical fluid experiments are sometimes limited by the number of raw materials to be extracted, and experiments can only be carried out in a small number. Experiments with relatively large-capacity extractor equipment will certainly not have as high accuracy as the process parameters obtained by small-capacity extractor equipment; Then a constant CO2 extractor capacity can no longer meet the experimental requirements, so we have introduced two CO2 extractors with different capacities (1L and 5L);

You can freely choose the appropriate container in the experiment, for example, use a 0.5-pound (1L) extractor Small-scale experiments are carried out on the equipment. When the experiment is successful, 2.5-pound (5L) extractor equipment is used to scale up the experiment to confirm the reliability of the process data and the possibility of large-scale production.

Read More: Supercritical fluid extraction

Standard Configuration Instructions

- Classic laboratory model, optimization-selling model. It has 2 extraction kettles (1L+5L), and the maximum working pressure is 500bar;

- There are also two separation kettles (1L+2L), and the maximum working pressure is 300 bar.

Features: Two CO2 extractors work alternately, and excess gas can be introduced into the extraction kettle to save gas; it also improves work efficiency. - The standard material is SUS304, (0Cr18Ni9); SUS316 is optional.

- The control system is a PLC touch screen; it can also be customized for manual control to reduce investment.

- Although it is a piece of small CO2 extraction equipment, it can also be used as an entry-level essential CO2 extraction machine for start-ups.

Nine Advantages of L-06 Small CO2 Extraction Machine

- Free choice between 1L and 5L laboratory supercritical extractor, owning an L-06 small CO2 extraction machine, in fact, has laboratory equipment for small and pilot tests.

- High-flow supercritical CO2

- Selective extraction, scalable experiment, adjustability, strict quality test

- 0.5-2 lbs/h variable frequency adjustable co-solvent adding system

- Full-spectrum oil and/or terpene extraction experiment without any solvent

- PLC control can be operated without any special skills

- The CO2 extraction flowchart panel controls the extraction and separation on and off

- The extract tests can be completed within 60 minutes.

- Including a one-year warranty and fast parts replacement, priority technical service, and contact with our scientific team.

Industry CBD Oil CO2 Extraction Machine/CO2 Essential Oil Extraction Equipment

The supercritical CO2 extraction machines are used to extract essential oils, including CBD oil, from hemp and cannabis plants. These machines operate by using high pressure and temperature to convert CO2 into a supercritical state, where it can penetrate into the plants’ tissues. The CO2 is used as a solvent to extract the desired compounds, including CBD, terpenes, and other cannabinoids, which are then separated and collected.

Industrial scale industry CBD oil CO2 extraction machine/CO2 essential Oil extraction equipment is available in different capacities, ranging from 10L to 9000L large-scale industrial extractors. The capacity of the machine depends on the size of the extraction chamber and how much plant material can be processed at once.

Fully automatic control of the entire process operation, automatic acquisition of data record storage, remote monitoring, and remote technical support is available with some BIT CO2 extraction machines.

The CO2 extraction process is known for producing high-quality, pure, and natural extracts from hemp and cannabis plants, free of any harmful chemicals and solvents. The extracts retain all the beneficial compounds, including terpenes, flavonoids, and other cannabinoids.

Advantages of CO2 extracted essential oils

- 100% Pure & Natural

- Free from leftover residues

- Therapeutic Properties

- Pleasurable Natural Aroma

- Free from adulteration

Advantages of CO2 extracted CBD oils

- Relatively inexpensive

- Non-toxic, non-flammable, and inert

- Can diffuse through plant material like gas and dissolve plant material like a liquid

- Leaves less residue upon being used in the extraction process compared to other solvents

- Easy to obtain and readily available in pure form

Video of CBD Oil CO2 Extraction Machine

Terpenes and Full-spectrum CBD oils

Terpenes are organic compounds that are found in plants, including cannabis and hemp. They are responsible for the distinctive aromas and flavors of different strains and varieties. Terpenes are also believed to have therapeutic effects, including anti-inflammatory, anti-anxiety, and pain-relieving properties. CO2 extraction preserves the terpenes in the final product, allowing for a more complete and effective experience.

Full-spectrum CBD oils extracted using CO2 extraction contain a range of cannabinoids, including CBD, THC, CBG, and others, as well as terpenes and other beneficial compounds. This is known as the “entourage effect,” where the combination of these compounds produces a more significant therapeutic effect than when taken individually. The entourage effect is believed to enhance the therapeutic benefits of CBD oils, making them more effective for a range of conditions.

What is Supercritical CO2 Extraction?

There are many solvents that can be used for supercritical fluid extraction. Different solvents have different critical properties, and different extraction processes require different solvents. Each solvent has different critical properties, such as temperature and pressure, that affect its solvating power, selectivity, and efficiency. The solvents that can be used for supercritical fluid extraction include ethane, ethylene, propylene, carbon dioxide, etc. CO2 is the preferred solvent.

Supercritical CO2 extraction is an environmentally friendly extraction method that uses supercritical CO2 fluid as an extractant. The supercritical CO2 fluid is in a thermodynamic state where the temperature is above the critical temperature, and the pressure is above the critical pressure, resulting in a unique combination of gas-like and liquid-like properties. This state allows CO2 to act as an efficient solvent, capable of extracting specific components from liquids or solids for separation purposes.

Principle

- Supercritical CO2 extraction is a process that involves using CO2 in its supercritical state as a solvent to extract desired compounds from a variety of materials. Supercritical CO2 refers to CO2 that has been heated and pressurized beyond its critical point, where it exhibits both gas and liquid-like properties.

- In the extraction process, supercritical CO2 is passed through the material to be extracted, where it dissolves the target compounds. The solubility of the target compounds can be controlled by adjusting the pressure and temperature of the CO2, allowing for selective extraction of specific compounds. The CO2 is then collected and depressurized, causing it to revert to gas and leaving behind the extracted compounds.

- Supercritical CO2 extraction is a versatile and effective method for extracting a wide range of compounds, including essential oils, lipids, and cannabinoids. It is also considered a safer and more environmentally friendly alternative to traditional solvent-based extraction methods, as it produces pure extracts without leaving behind any residual solvents or contaminants.

Features

Supercritical CO2 extraction can be carried out near room temperature (35-40°C) and under the cover of CO2 gas, which effectively prevents the oxidation and escape of heat-sensitive substances. Therefore, the active ingredients of medicinal plants are maintained in the extract, and the substances with high boiling point, low volatility and easy pyrolysis can be extracted at a temperature far below their boiling point;

The use of supercritical CO2 extraction is the cleanest extraction method because the whole process does not use organic solvents, so the extract has no residual solvent substances, thus preventing the existence of harmful substances to the human body and the pollution of the environment during the extraction process, ensuring 100% pure naturalness.

Ten Features

- Select a suitable solvent such as CO2 to operate at a lower temperature and an oxygen-free environment to separate and refine heat-sensitive substances and easily oxidized substances;

- Supercritical fluid has good permeability and solubility, and can quickly extract active ingredients from solid or viscous raw materials;

- Reduce the density of the supercritical phase, it is easy to separate the solvent from the product, there is no solvent pollution, there is no phase change process in the recovery of the solvent, and the energy consumption is low;

- It has the dual functions of distillation and extraction and can be used for the separation and purification of organic matter.

- CO2 has good mutual solubility with most organic compounds, and CO2 liquid has greater volatility than extractives, which makes the separation of extractants and extracts easier;

- CO2 extraction allows for precise control over the extraction process, resulting in consistent and reproducible results;

- The critical pressure (7.38MPa) is low and easy to reach; The critical temperature (31.1℃) is low and the enthalpy of vaporization is low, which is more suitable for industrial production;

- Good selectivity can be adjusted to extract specific compounds by varying temperature and pressure conditions, supercritical CO2 exhibits excellent solubility for low molecular weight aliphatic hydrocarbons and low polar lipophilic compounds, such as esters, ethers, lactones, etc.;

- The CO2 has chemically inert, has no danger of combustion and explosion, no toxicity, no corrosiveness, no erosion to equipment, and no pollution to products and the environment; and cheap, high-purity CO2 is easy to obtain;

- High-quality extracts that are free of residual solvents and contaminants. In the extraction system, a high concentration of CO2 has the effect of sterilization and anti-oxidation on the product.

Uses of

Supercritical CO2 Extraction Machine

Using supercritical fluid extraction (SCFE) technology to extract natural substances, CO2 is the preferred solvent, because the unique characteristics of supercritical CO2 fluid determine that the application range of supercritical CO2 extraction is very wide.

Depending on the customer‘s request, we can offer Supercritical CO2 Extractors made of different grades of extraction capacity, pressure, and supercritical fluid fractionation equipment, depending on the application

- Pharmaceutical industry: used for the extraction of active ingredients of Chinese herbal medicines, the purification of heat-sensitive biological products, and the separation of lipid mixtures;

- Food industry: extraction of hops, extraction of pigments;

- Fragrance industry: refining of natural and synthetic fragrances;

- Chemical industry: separation of mixtures.

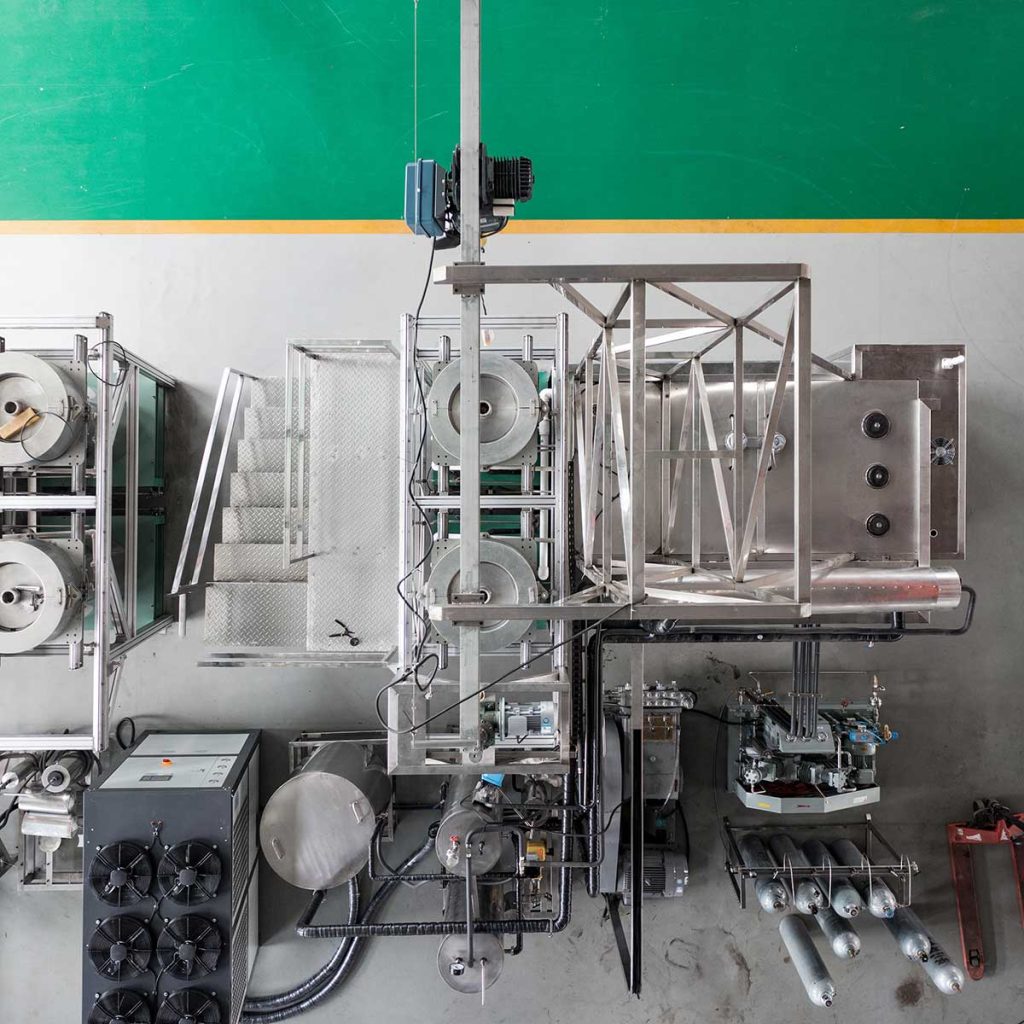

How it’s Composed

Our custom solutions incorporate and build on our more than 30+ years of real-world extraction experiments and CO2 extraction machine manufacturing experience,thousands of lab small CO2 extraction machines, pilot-scale CO2 extractors, and industry supercritical CO2 extraction machines have been provided to global customers.

Because the extraction process of each laboratory and industrial production is different. In BIT, the CO2 extractors all are custom system and includes a co-solvent system and a touch screen control system. Provide the optimization solution for every individual extraction goal and program.

- Extraction system: generally consists of 2 to 3 vessels (up to 6, divided into two groups, the maximum working pressure is between 35 and 50MPa, special customization can reach 105MPa, and the maximum working temperature is 85°C.

- Separation system: Popular CO2 extraction machines are usually equipped with 2 to 3 extraction vessels and 3 separators: Waxes separation and Light oil separation in 1st separator. Light oil separation in 2nd separator. To trap the lightest and most volatile compounds in 3rd separator.

- Supercritical fluid creation and closed-loop operation system: a supercritical CO2 fluid system composed of a CO2 high-pressure pump, filter, mixer, and fluid transfer line, where CO2 liquid is created by the high-pressure pump into a supercritical fluid to dissolve extraction in biomass The target, depressurized separation extract becomes the liquid cycle again.

- Heat exchange system: responsible for providing the energy required for temperature regulation in the extraction vessel and separation vessel

- Control system: CNC control real-time automatic control of the temperature, pressure and flow of the extraction machine.

How it Works?

The extremely low surface tension, low viscosity, high diffusivity, and tunable solvent strength of supercritical CO2 make it an ideal solution for a wide variety of industrial and scientific applications.

Extraction and separation are combined into one. When the saturated supercritical CO2 fluid of the dissolved substance enters the separator, due to the pressure drop or temperature change, the CO2 and the extract quickly become two-phase (gas-liquid separation) and are immediately separated.

- The biomass is dried to a moisture content of less than 10%;

- Grind biomass to 40-60 mesh;

- Put the biomass into the extraction basket and put it into the extraction vessel;

- Start the CO2 extraction machine, introduce CO2 gas into the extraction vessel and create a supercritical CO2 fluid;

- Adjust the pressure, temperature, and CO2 flow in the extraction vessel to meet the requirements of the extraction target of biomass;

- Adjust the pressure and temperature of the separation vessel group according to the requirements of the extraction target, so that the CO2 fluid loses the supercritical state to a liquid so that the CO2 extract is successfully separated from the gas, and different CO2 extracts (heavy components and light components);

- The CO2 liquid is introduced into the gas intermediate storage tank in a closed loop;

- The CO2 liquid starts from the gas storage and the intermediate storage tank, and passes through the filter to create the supercritical CO2 fluid again for the next cycle;

- After the allotted run time, the system is depressurized by releasing CO2 through Separator 1 or 2 to obtain the CO2 extract.

About Us

China high-quality supercritical CO2 extraction machine/co2 essential oil extraction equipment manufacturer.

Borisbang Industrial Technology (BIT) was established in the year 1989 and has over 30 years of experience in the field of supercritical fluid extraction. We need no introduction in the Supercritical Fluid world. Having a solid trained technical team with a wide range of quality Supercritical Fluid Systems, and On-Time Deliveries, we have been accumulating happy customers worldwide.

Our core focus and specialization is in the Supercritical CO2 Fluid Extraction Machines.