supercritical carbon dioxide dyeing

waterless dyeing machine

WATERLESS DYEING MACHINE

COMPOSITION

Waterless dyeing machine/supercritical CO2 dyeing machine includes dyeing, separation, pressurization, heat exchange, heating, refrigeration, safety, electrical, instrument automatic control,data transmission remote monitoring, recovery, Inflation and other different functional systems.

2250L supercritical CO2 waterless dyeing machine

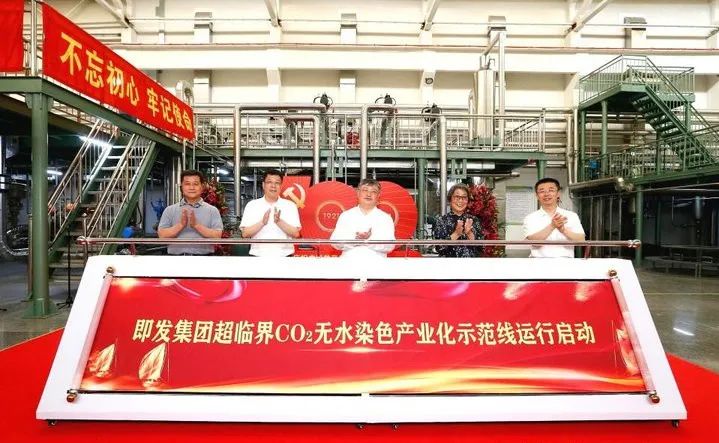

2250L supercritical CO2 waterless dyeing equipment has been continuously and stably produced in Qingdao Jifa Group Base for five months in 2022

Waterless dyeing machine customization

| Scale | Volume | Feature |

| Lab | 1~10L | Complete configuration, wide parameters, suitable for supercritical CO2 dyeing; Customizable and expandable; safe and reliable; Excellent performance, simple operation, stable and reliable experimental data; High-quality pipe fittings to avoid cross-contamination; Easy to clean, maintain, maintain and replace parts; Suitable for laboratory use. |

| Pilot | 10~500L | Unique design, uniform dyeing; The process is reasonable, the parameters can be customized, the heat and mass transfer efficiency is high, and the energy consumption is low; Equipped with safety devices, safe and reliable; Quick opening structure, good airtightness, simple operation; High-quality fittings and pipelines, no cross-contamination; Automatic control, product quality and experimental data are stable and reliable; It is suitable for obtaining design basis for industrialization scale-up; |

| Industrial | 500L~ | Process research, dye development, and equipment structure design for a variety of different fabrics, and specific process routes and configuration schemes will be tailored according to the actual needs of customers, and then industrialized and scaled up. |

WATERLESS DYEING

Supercritical Fluid Dyeing (SFD), also known as Waterless Dyeing, is a new dyeing technology with broad prospects.

At present, the supercritical CO2 dyeing technology often uses CO2 as the medium.

Because the solubility of supercritical CO2 to organics varies with solute polarity, molecular weight, density, etc., it is easier to dissolve non-polar or weakly polar, and small molecular weight organics; and the dyes used in dyeing have weak polarity and low molecular weight. Large, so it is easily soluble in supercritical CO2.

Moreover, the dye molecules dissolved in supercritical CO2 are messy and dispersed. In this state, the dye can quickly reach the surface of the fiber and easily penetrate into the fiber, making it easier to achieve the purpose of dyeing the fiber with the dye.

WATERLESS DYEING PROCESS

Introduce

Fluid formed by the medium gas in the supercritical state has low viscosity, can automatically dissolve the dye and has high diffusivity.

The solubility of dyes in supercritical CO2 fluids increases with the increase of fluid density, so by adjusting the pressure and temperature to control the CO2 density, you can control the solubility of dyes in CO2 fluids, and then reduce the fluid density by increasing the temperature. And the dispersibility of the dye in the solution can promote the dye to diffuse into the fabric fibers more quickly.

Parameters of the supercritical CO2 dyeing process can be more accurately controlled and adjusted more quickly.

Supercritical CO2 dyeing process

Process of dyeing with supercritical CO2 fluid is very simple.Dyeing is usually carried out under a high pressure of 150-350bar, and the dyeing temperature is adjusted according to the type of fabric, which is greater than the glass transition temperature of the fiber, generally 80-160℃, but it can be higher. The dyeing time is generally 10-120min.

- Put the warp beam winding the dyed material in the high-pressure dyeing kettle, put the dye in the dyeing kettle, and close the pressure vessel;

- CO2 is compressed to a supercritical state by the pump and heated to a specified temperature by a heater.

- The supercritical CO2 fluid dissolves the dye in the dye tank and is sent to the dye tank. The dye fluid is circulated through a circulating pump, so that the dye is absorbed by the fiber.

- After dyeing, the dye liquor is decompressed through a separator.

- At this time, CO2 becomes a gas, and the solubility of the dye in it decreases and precipitates, thereby separating the CO2 and the dye; the CO2 without the dye is recovered and stored.

- On the other hand, the CO2 cycle in the dyeing tank is stopped, the high-pressure dyeing kettle is turned on, and the dyed product is taken out.

Features of Waterless Dyeing

Since supercritical CO2 has the characteristics of high surface tension, low viscosity, high diffusion coefficient and easier solubility with dyes, compared with traditional dyeing technology, the characteristics of supercritical CO2 dyeing technology are as follows:

- Not use water at all, so there is no wastewater treatment problem;

- No drying process for textiles after dyeing, which saves energy;

- No need to add surfactants or other additives;

- Color is more vivid than traditional dyeing;

- Dyes and CO2 are easier to recycle;

- Dyeing temperature is lower than traditional dyeing temperature;

- Whole process is simpler than the traditional process;

- It is suitable for dyeing materials that are difficult to dye with water.

Waterless dyeing machine Cost and supercritical CO2 dyeing machine price

Our supercritical CO2 dyeing equipment price is lower than our peers’, and our waterless dyeing machine is high quality, we have our own manufacturing factory, all products are factory price, there is absolutely no middleman markup, we accept both small batch scale customer and large industrial batch scale wholesale CO2 dyeing machines and waterless dyeing machines for sale online