herb oil extraction machine

R-700T 700L×3 Supercritical CO2 Extraction Machine

It is never to late to improve the performance of your herbal oil extraction processes.

Since 1989, expert in co2 herb oil extraction machine.

Wide application. Could used for nontoxic extraction for the flower, plant, leaf, pericarp

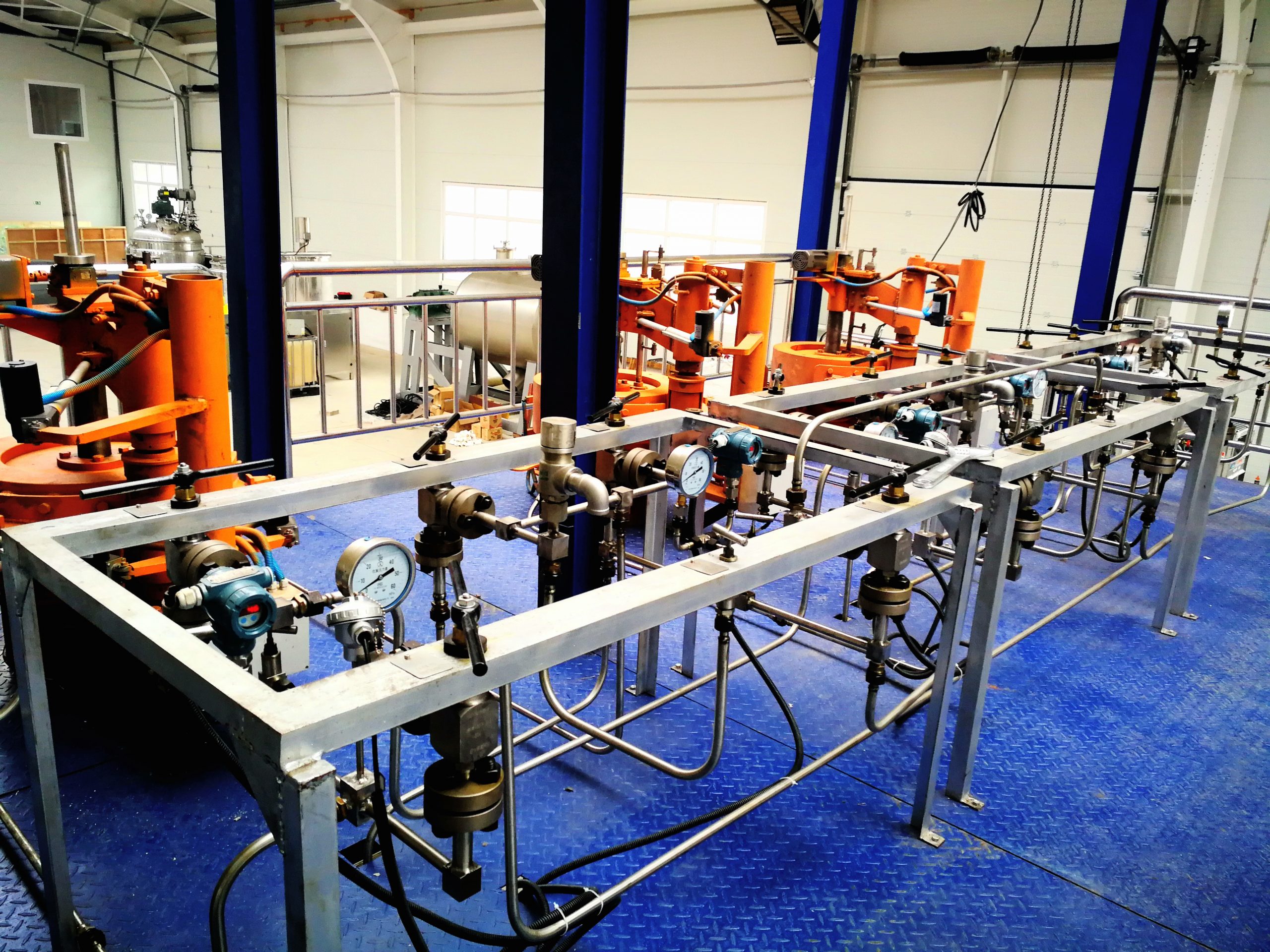

Supercritical CO2 extraction machine with three extractors

The supercritical CO2 extraction machine designed with three extraction kettles has been widely used in industrial production.

The three extraction kettles can work in series and in parallel.

We recommend to perform CO2 extraction in parallel, which has the highest efficiency; because in parallel extraction, there are always two extractors in the CO2 extraction state, and the third extractor is waiting for the next time after unloading biomass.

In this way, 22 extraction batches can be carried out in 24 hours. This is a semi-continuous extraction method, and the CO2 extraction system with three extractors is a very efficient machine.

At the beginning of 2014, we conducted a statistics. There are about 15 sets of supercritical co2 extractors designed with three extractors in China; the minimum volume of a single extractor is 200L and the maximum is 3500L; and these industrial-grade CO2 extraction systems are large Part of the main work is the extraction of vegetable oils.

2100L Supercritical CO2 Extractor

A supercritical CO2 essential oil extraction machine composed of three 700L extractors, used for CO2 extraction of herbal oil, hemp/hemp/hemp oil, and rose essential oil.

The R-700T supercritical CO2 herb extraction machine has three extraction kettles and two separation kettles. The extraction working medium is carbon dioxide. The working medium can be recycled during the working process. It is equipped with a cosolvent system with a flow rate of 100L/h.

The R-700T supercritical CO2 herb oil extraction machine covers an area of about 500 square meters and has a net height of 10 meters. The equipment is fully automatic control equipment. The extraction and separation pressure and temperature are automatically controlled and can be remotely monitored by a computer. Both the series and parallel operations of the valves are manually controlled. During the working process, the maximum working pressure of each extraction kettle is controlled by a four-fold method of pressure detection sensor, safety valve and control signal interlocking, which is safe and reliable.

The R-700T supercritical co2 oil extractor extraction kettle cover adopts a clamp-type hydraulic automatic quick-opening structure. The inner walls, pipes and pipe fittings in contact with the materials are made of stainless steel with acid and alkali resistance and suitable for food hygiene requirements. The equipment in the system to extract the process medium CO2 can be recycled to maximize the use of CO2.

2100L supercritical CO2 extraction machine configuration parameter

| EXTRACTOR | SEPARATOR | ||

| Volume | 700 L, 3 sets | Volume | Ⅰ 300 L, Ⅱ Ⅲ 240L |

| Max Working Pressure | 350bar | Max. working pressure | Ⅰ 180bar, Ⅱ Ⅲ 120bar |

| CO2 HIGH PRESSURE PUMP | CO-SOLVENT PUMP | ||

| Outlet pressure | 350 bar | Outlet pressure | 350 bars |

| Max. flowrate | 4000L/h | Tank/Max. flowrate | 200L / 100L/h |

| CO2 OUTSIDE TANK/PUMP | (SUPPLIED BY BUYER) | PARAMETERS CONTROLLER | |

| Volume/Pump | 3000L / 1500L/h | Parameters control | PC-based software with recipe for automation |

| Working pressure | 85 bar / 100bar | Datalogging | Included |

| TAIL GAS BUTTER TANK | |||

| Volume | 1000L | ||

| Working pressure | 60 bar |

Extraction Guide: CO2 Extracted Herbal Oil

Efficient. Clean. Safe. Versatile.

Advantages of CO2 extraction process of herbal oils

Supercritical CO2 extraction technology is applied to herbal medicine, mainly including extraction and separation, extraction and separation and concentration, removal of organic solvents and removal of impurities.

The supercritical CO2 extraction technology can extract and separate the effective components of traditional Chinese medicine volatile oils, fatty oils, coumarins, terpenes, alkaloids, ketones, esters, etc., which can be basically completed independently, and has unparalleled performance in other technologies. Superiority.

BIT’s Herbal Oil CO2 Extraction Experience

Over the past 30 years, some of the herbal raw materials manufactured by BIT supercritical CO2 extraction device have been tested or produced by BIT:

Ligusticum chuanxiong hort, Angelica, Safflower, Woody, Dalbergia, Cumin, Spice, Peppermint, Houttuynia, Evening Primrose, Nutmeg, Angelica, Turmeric, Magnolia, Alisma, Rhodiola, Artemisia annua, Sand Kernel, Chuanxinlian, Tanshinone, Lycium barbarum seed, Ganoderma lucidum spore powder oil, Propolis, Nicotine, Theophylline, Capsaicin, etc.

HOW TO CHOOSE THE RIGHT CO2 EXTRACTOR?

CO2 Extraction Machine Buyer’s Guide

As you can imagine, not all supercritical CO2 extractors are made the same.

For more than 30 years, we have customized many CO2 extraction machines (Tabletop CO2 Extractor) for many companies and university laboratories (1 lb CO2 extractor). Because each customer’s CO2 extraction process requirements are different, there are almost no identical machines.

How many liters of CO2 extraction vessels are needed?

The first factor that determines the size of the CO2 extraction vessel is the daily working hours of the plant, which determines the daily extraction batch. The vessel size of the CO2 extractor depends on the biomass to be processed per day.

How many separators are needed?

How can I custom my separator when I need more terpenes in my How can I custom my separators when need more terpenes in CBD oil extraction process? Waxes separation and Light oil separation in 1st separator; Light oil separation in 2nd separator; To trap lightest and volatile compounds in 3rd separator. It is important to choose the right vessel size that will meet your current needs as well as future demand.

How many pressure is optimization for your CO2 extraction process requirements?

The choice of CO2 extraction pressure is a changing factor. If the extraction pressure is too high, the useless substances in the plant will be extracted, such as wax and chlorophyll. If the extraction pressure is too low, the extraction time will be increased.

How can the minimum operating costs be achieved?

Further Reading: CBD Oil CO2 Extraction Machine

Complete herbal CO2 extraction process steps

- Fill Crushed Herbs: Load Extraction Vessel with biomass.

- Pressurize with CO2: Bring each vessel to working pressure (supercritical co2 fluid) using CO2 from supply cylinders.

- Run in Closed Loop: In Extraction Vessel, compounds are pulled from biomass into solution.

Solvent (CO2) is boiled out of solution in Separator 1.

Evaporated CO2 is condensed into liquid and stored in Accumulator. - Periodically Sample Extract: Open separation valve on the separation system to collect extraction samples use the Vessel.

- Depressurize: After allotted run time, system is depressurized by releasing CO2 through Separator 2 or Separator 3 (If there is).

- Collect Extract: Extract collected from the Vessel.

Read More ↗

Here we have compiled some articles about Supercritical Fluid (SCF) in the station, hope they can help you.

herbal oil co2 extraction process

Herbal oil CO2 extraction method

After 30 years of extraction experience, we believe that there are quite a few varieties of herbal medicines that can be extracted using supercritical CO2 alone. The key is how to choose a good variety or use a good entrainer

Extract different target compounds in one extraction batch

Because of the stability and flexibility of BIT’s CO2 separation

system, a crude fractionation can be accomplished with the BIT standard herbal essential oil CO2 extraction systems.

BIT CO2 separation systems are capable of modulating the pressure and temperature of CO2. Setting up the desired parameters enables us to manipulate its solvent properties. With the right pressure, temperature, density, and extraction time, we can target the desired compounds we want to extract. This means we can extract the target compounds and separate them into different portions, all in a single extraction cycle!

BIT CO2 extractors are also equipped with several separator (collection) vessels. As the extract laden CO2 exits the extractor vessel it cascades through these separators. The first separator is set at the highest pressure in the series. The 2nd and 3rd separators ramp downwards in pressure. Different molecular weight compounds drop out at different temperatures and pressures, thus allowing for the fractionation to take place in individual separators.

In a standard fractionation scenario, waxes are dropped out in the first separator, heavy oils and resins in the 2nd separator and light oils in the 3rd.

Ligusticum Chuanxiong Hort Herbal Oil CO2 Extraction Process

Extraction goal

To obtain high-purity volatile oil for injection.

CO2 Extraction process

The raw material is crushed into 40 meshes, the extraction pressure is 7.8MPa (subcritical state), the temperature is 31.8°C (fluid temperature), the separation Ⅰ pressure is 6MPa, the temperature is 30°C; the separation Ⅱ pressure is 5.6MPa, the temperature is 25°C, the cycle is 2 hours, and the yield is 2.8 About% (except for moisture).

CO2 Extraction Process of Saussurea lappa Clarke Herbal Oil

CO2 Extraction mothed

The raw material is crushed to 60 mesh, the extraction pressure is 28MPa, the temperature is 32°C; the separation I pressure is 6MPa, the temperature is 45°C; the separation II pressure is 5MPa, the temperature is 25°C, the cycle time is 1.5-2 hours, and the yield is 3%.

CO2 Extraction Process of Houttuynia Herbal Oil

Respectively steam distillation method, organic solvent extraction method and supercritical CO2 extraction method. For the extraction experiment of Houttuynia cordata volatile oil, supercritical CO2 extraction takes the extraction pressure, temperature, and flow rate as the three parameters, and designs the three-factor four-level orthogonal test.

CO2 Extraction method

The raw material is crushed to 40 meshes, the extraction pressure is 20MPa, the temperature is 35°C, the CO2 flow rate is 40Kg/h, and the extraction rate is 1.76%.

Influence of different extraction methods

- Steam distillation: dark yellow color, strong smell, time 6h, extraction rate 0.042%

- Petroleum ether extraction: orange-yellow color, strong odor, time 12h, extraction rate 0.084%;

- Supercritical CO2 extraction: light yellow color, pure smell, time 1.5h, extraction rate 1.76%.

Supercritical CO2 extraction of Houttuynia cordata volatile oil is superior to the other two traditional methods in terms of color, smell, extraction rate and time.

CO2 Extraction Process of Angelica Herbal Oil

CO2 Extraction mothed

The raw material is crushed 80-100 mesh, the extraction pressure is 25MPa, the temperature is 35°C; the separation I pressure is 8MPa, the temperature is 45°C; the separation II pressure is 5.6MPa, the temperature is 35°C, the cycle time is 1.5h, and the extraction rate is 1.3%.

CO2 Extraction Process of Turmeric Oil

Raw material crushed 40 mesh, extraction pressure 20MPa, temperature 25°C, distillation column pressure 9MPa, temperature 30-50°C (four-section gradient); separation Ⅰ pressure 6MPa, temperature 45°C; separation Ⅱ pressure 5MPa, temperature 30°C, extraction rate 7.5%, light-colored cosmetics, dark-colored medicinal use.

Read more↗ Turmeric Oil

CO2 Extraction Process of Ganoderma Spore Oil

CO2 extraction mothed

Raw material Ganoderma lucidum broken spore powder, the main effective ingredients are oleic acid, linoleic acid, triterpenes, etc., extraction conditions: extraction pressure 28-30MPa, temperature 40℃, extraction rate 20-28%. The origin of the raw materials is different, and the extraction efficiency is different.

Read More↗ Supercritical CO2 extraction of Ganoderma lucidum Spores oil

Simply the most complete

CO2 extraction process you can find

CO2 Extraction Process

From raw material preparation, we offer you the most complete CO2 essential oil extraction process.

At the same time, more than 100 CO2 essential oil extraction methods from the laboratory are also provided for you.

how to extract essential oils

Detailed explanation of CO2 extraction process steps of plant essential oils。

how to extract cbd

About the co2 extraction machine cannabis.

You can read a lot of articles about cbd oil extraction from the Internet, but I can tell you for sure that they are not comprehensive at all, and even have wrong descriptions.