Supercritical Fluid Equipment

Supercritical fluid system, extraction, drying, dyeing, cleaning, chemical reaction, making nanoparticle,machine,equipment

What Is Supercritical Fluid

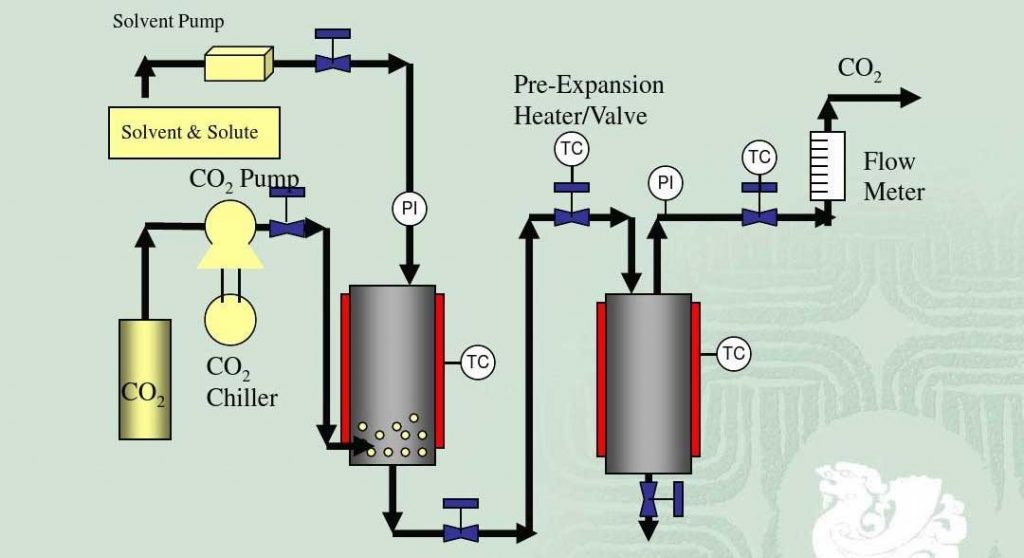

Among several supercritical fluid (abbreviated SCF) technologies, the earliest developed, most researched and industrialized product technology is undoubtedly the supercritical CO2 fluid extraction (abbreviated SFE) technology.

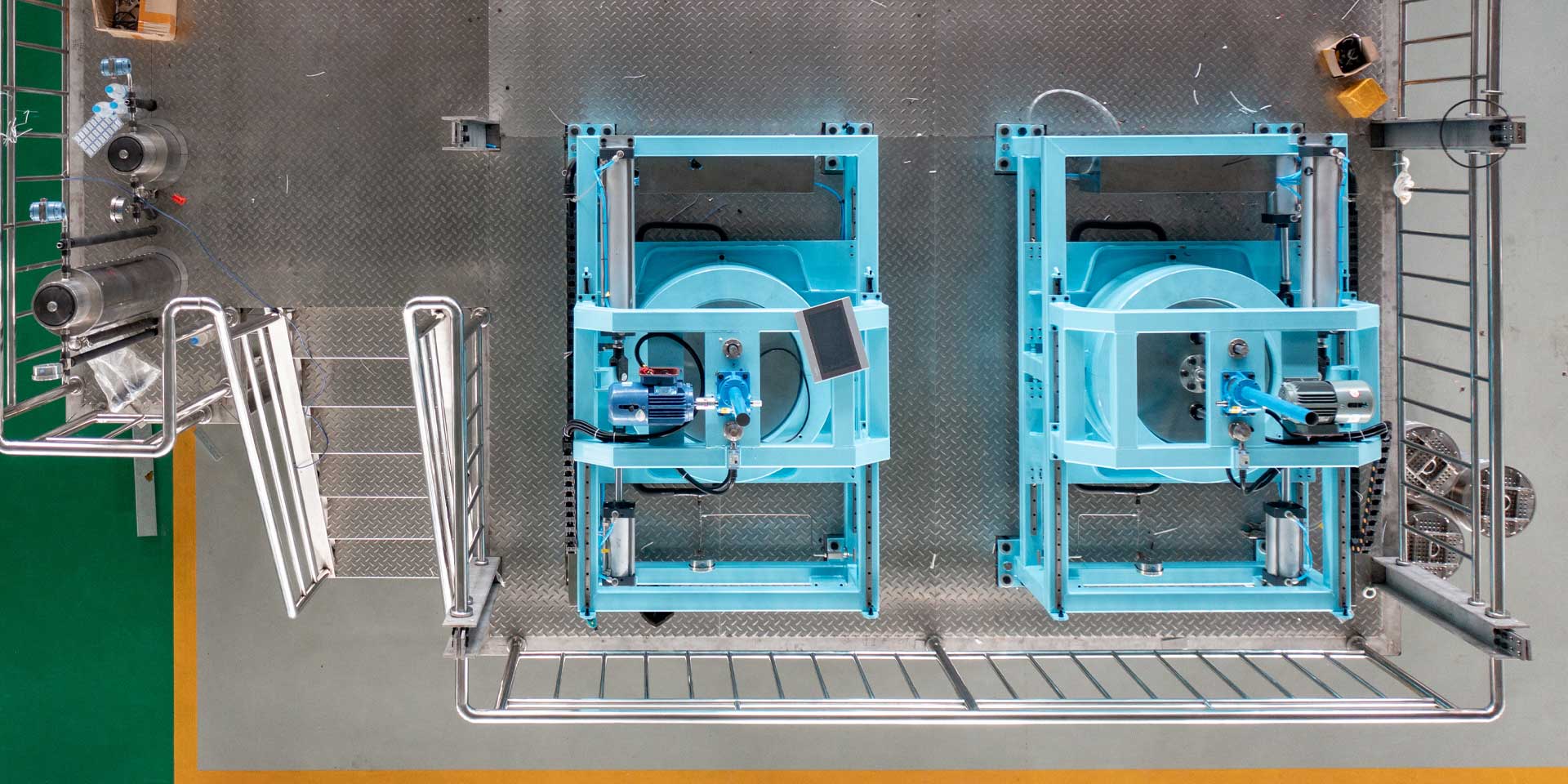

Supercritical Fluid Equipment

Apply supercritical fluids to various fields in production and life, such as energy saving, natural product extraction, polymerization reactions, ultrafine powder and fiber production, spraying and coatings, catalytic processes and supercritical chromatography to obtain products with certain characteristics. It is supercritical fluid equipment.

Since 1989, BIT has been manufacturing Supercritical Fluid Processing Equipment Systems for extraction, separation, drying, dyeing, micronization, cleaning and reaction processes. The capacities of these machines range from small benchtop units in the laboratory to industrial production units with a capacity of several thousand liters.

supercritical CO2 Extractor

Extraction pressure: 35MPa-105MPa; Extraction capacity: 200mL-9000L; Laboratory scale CO2 extractor…

APPLICATION OF SUPERCRITICAL FLUID EQUIPMENT

Supercritical Fluid Extraction Equipment

Food industry

The CO2 extraction process using supercritical fluid extraction equipment can decaffeinate coffee beans, de-cholesterol in dairy products, extract unsaturated fatty acids DHA/EPA from fish oil, extract active ingredients in hops, and extract food additives from natural plants, Food flavoring, food coloring, etc.

Pharmaceutical industry

Supercritical carbon dioxide exhibits excellent solubility for low molecular weight aliphatic hydrocarbons and low polarity lipophilic compounds such as alcohols, ethers, aldehydes and lactones. In the production of antibiotic drugs, it is very difficult to completely remove the solvent without deteriorating by traditional methods. The use of supercritical CO2 extraction process fully meets the requirements.

At present, many companies in the world have used the CO2 extraction process of supercritical fluid extraction equipment to extract various medical and health ingredients oil from sea buckthorn seeds, perilla seeds, flax seeds, grape seeds, wheat germ, tomato seeds, almonds, etc., and the traditional Chinese medicine Artemisia annua The antimalarial drug artemisinin extracted from CBD, CBD OIL extracted from cannabis, and soft phospholipids extracted from egg yolk have unique curative effects on cardiovascular and cerebrovascular diseases.

Fine Chemicals

The most widely used supercritical CO2 extraction process in fine chemicals is the extraction of natural spices, such as from Xuxianghua, spice plants such as osmanthus, jasmine, and chrysanthemum. Extract essence from lavender, rosemary, etc., extract agarwood essential oil from agarwood, extract essential oil from plant seed kernels, extract spices from pepper, cinnamon, mint, etc.

Chemical reaction

Enzyme catalysis

In the experiment of enzyme catalyzed reaction using supercritical fluid equipment, it is found that supercritical carbon dioxide fluid as solvent can promote the enzyme catalyzed reaction. And the enzyme is insoluble in supercritical carbon dioxide, and the separation and recovery of the enzyme is easy.

Hydrogenation reaction

The hydrogenation reaction mainly refers to the hydrogenation reaction of CO2 and CO. Supercritical fluid is not only a reaction medium, but also a reactant, which has great value.

Water oxidation

As long as the oxidation reaction refers to the oxidation reaction that occurs in supercritical water, the reaction utilizes the supercritical water’s super-dissolving ability to oxygen and organic matter to oxidize organic matter into water, CO2, nitrogen and salt in a short time under homogeneous conditions. and other non-toxic small molecule compounds. The supercritical water oxidation technology of supercritical fluid equipment is efficient and thorough (the removal rate of toxic substances is as high as 99.99% or more under appropriate conditions), the reaction speed is fast, the residence time is short, the structure of the reaction equipment is simple, and the scope of application is wide (applicable to various Toxic substances, waste water and waste treatment), no secondary pollution (clean products, easy separation of inorganic salts, and waste water can be completely recycled after treatment), etc.

Biodiesel

The preparation of biodiesel by supercritical methanol is a new process for preparing biodiesel from vegetable oil, animal oil or waste oil. Compared with the chemical method, the methanol method of supercritical fluid equipment has many advantages in terms of reaction speed, requirements for raw materials and recovery of products. From the analysis of the cost and economic benefits of biodiesel, biodiesel is a non-toxic, biodegradable and renewable alternative fuel for engines.

Material manufacturing

The application of supercritical fluid equipment in the field of materials mainly focuses on the preparation of fine particles, involving polymer materials and their modification, inorganic and organic materials, etc. Mainly for supercritical fluid drying technology and supercritical micronization.

Supercritical drying equipment

When the dried material is placed in a supercritical environment, the gas/liquid interface disappears, there is no liquid surface tension, the drying process is mild, and the damage to the material structure due to drying stress is avoided;

Due to the high diffusion coefficient of supercritical CO2, its dehydration and drying speed is high;

Drying and dehydration are carried out under high pressure, and the dehydration process also has a bactericidal effect.

Supercritical Micronization Equipment

Supercritical fluids have solubility for many solutes and this solubility can be adjusted with operating temperature and pressure, constituting a new technology for the preparation of ultrafine particle materials. In the specific operation of supercritical fluid micronization equipment, there are two ways to achieve, namely rapid expansion method and anti-solvent method.

The rapid expansion method is mainly used in: inorganic and ceramic materials that are difficult to pulverize, such as SiO2 and Al2O3; polymer materials that are difficult to grind, such as polyvinyl succinate and polypropylene; heat-sensitive organic substances soluble in supercritical fluids, such as drugs.

The anti-solvent method is mainly used for: explosive substances that are sensitive to operating temperature and impact, such as octogen (HMX); heat-sensitive biologically active substances, such as hormone proteins; organic substances that cannot be dissolved in a single supercritical fluid, such as drugs, high Molecular and organic dyes, etc.

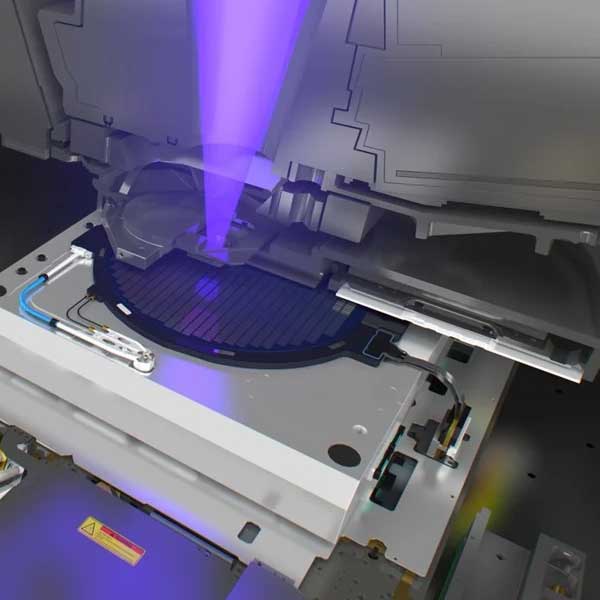

supercritical cleaning

The molecule of CO2 is smaller than that of water, and the cleaning time can be shortened in the supercritical state, and there is no problem of drying after cleaning.

CO2 cleaning of supercritical fluid equipment has advantages in terms of technology, economy and environmental protection, such as high removal efficiency of pollutants, low solvent and energy consumption, no volatilization of organic solvents in the process, no toxic and flammable solvents involved, There is no need for drying and solvent post-treatment procedures, simple and low-cost recycling of CO2, and no solvent waste liquid and waste water are generated.

supercritical dyeing

Compared with the traditional water bath, the dyes in the supercritical CO2 fluid medium have better level dyeing on polyester fabrics, excellent color fastness to washing and dry and wet rubbing fastness, which can save the post-dyeing treatment process in the traditional water bath method. , shorten the process flow. The CO2 dyeing technology of supercritical fluid equipment is a new type of dyeing technology with good prospects. Using CO2 as the medium, the dyeing process does not produce pollution, which fully reflects the concept of clean production.

Supercritical fluids degrade waste plastics

Depolymerization in supercritical medium utilizes the excellent solubility and mass transfer properties of supercritical fluids to decompose or degrade polymer wastes in garbage to obtain gas, liquid and solid products. Gases and liquids can be used as fuel or chemical raw materials, viscous paste products can be used as waterproof coatings or adhesives, and the remaining residue can be used as paving or other building materials.

Safe and efficient “super” disinfectant

CO2 supercritical fluid under high pressure can effectively kill all kinds of bacteria, and it is very likely to become a new sterilization technology to replace the controversial radiation sterilization method. Sterilization experiments under working conditions (20MPa, 35℃, 2h, relative humidity of 70% to 90%) showed that the reduction ratio of baker bacteria, Escherichia coli, Staphylococcus, Aspergillus niger and Bacillus subtilis reached 99%. At present, medical textiles are routinely sterilized by high-pressure steam, or treated with epoxy hexane, peracetic acid, etc. These traditional methods are either highly corrosive to equipment, or are cumbersome to operate, and also cause damage to fibers.

The new technology uses a small amount of disinfectant to use liquid CO2 as a carrier or directly uses CO2 in a supercritical state to have a better disinfection effect. Fiber also has a good protective effect.

Supercritical Chemical Analysis

Supercritical fluid can be used as mobile phase for chromatographic analysis, and has the advantages of fast analysis speed, good selectivity, high separation efficiency, and mild analysis conditions. Under the same conditions, the analysis speed is about 4 times that of liquid chromatography, and it is widely used in the analysis of samples such as olefin polymers, styrene polymers, glycerides, higher alcohols, amino acids and polycyclic aromatic hydrocarbons.