CO2 Micronization Equipment for Pharmaceuticals

SUPERCRITICAL CO2 FLUID MICRONIZATION EQUIPMENT

Supercritical CO2 Micronization Equipment

BIT supercritical micronization equipment uses supercritical micropowder technology to process and prepare particles, microspheres, microcapsules, porous materials, liposomes and other fine materials.

Supercritical finely controlled particle stream quickly passes through the nozzle hole, and the sudden expansion of CO2 produces a nanoparticle stream.

Supercritical fluid micronization

Supercritical fluid micronization technology is a new method for preparing ultrafine particles. Supercritical fluid crystallization preparation conditions are mild and do not need to be in contact with the solvent.

Resulting particles have small particle size and uniform distribution, which is especially suitable for the miniaturization of heat-sensitive and easily oxidized biologically active substances.

Supercritical fluid micronization classification

At present, supercritical fluid micronization/supercritical fluid nanofabrication technology is used to prepare ultrafine particles. According to its principle, it can be divided into supercritical solution rapid expansion method (RESS) , Supercritical Antisolvent Method (SAS) and gas saturated solutionsedimentation method (PGSS).

According to the operation mode, the supercritical fluid solvent method is divided into three different modes: liquid batch operation, gas batch operation, and continuous operation.

Principle of RESS method

A certain degree of solubility of the solute in SCF is a necessary condition for the RESS process to proceed.

First, the solute is dissolved in the SCF, and then the supercritical solution is expanded in a very short time (10-8 ~ 10-5s) through a fine nozzle.

During the expansion process, the sudden change of pressure and temperature causes the solute supersaturation to rise suddenly, and a large number of micronuclei are precipitated, and they grow rapidly in a very short period of time to form uniform micron or nano-sized particles.

Principle of SAS method

The SAS method uses SCF as an anti-solvent, dissolving the material to be prepared into a certain organic solvent to make a solution, and mixing this solution with a supercritical fluid.

Although the supercritical fluid is basically insoluble to the solute in the solution, the solvent in the solution can be miscible with the supercritical fluid.

When the solution and the supercritical fluid dissolve each other, the volume of the solution will expand, which will greatly reduce the dissolving ability of the original solvent and cause the solute to separate out.

Principle of PGSS method

The PGSS method dissolves supercritical CO2 into a liquid solute or a suspension of solute. After reaching saturation, this high-pressure gas-liquid or gas-liquid mixture is rapidly expanded and depressurized through a nozzle to form an aerosol.

The CO2 in the aerosol H2O volatilizes at high temperature in the expansion chamber, solute precipitates, and fine particles are produced.

Difference of supercritical micronization equipment

RESS method has a simple device and can be achieved by using only one nozzle when producing a small amount of material. But the biggest limitation of the RESS method micronization equipment is that the solubility of SCF for most substances is too small.

SAS method micronization equipment is more widely used, especially for the production of high-quality drugs, food additives, cosmetics, etc. The nature and composition of these substances are controlled by controlling the operating conditions, but these methods have disadvantages such as relatively complicated processes and high investment costs.

PGSS method micronization equipment is simple in principle, low in equipment cost, and has a wide range of applications, but the prepared particle size is uncontrollable and the particle size is relatively large.

How to choose CO2 micronization equipment ?

When choosing a method to manufacture fine particles, various factors must be considered comprehensively, such as the solubility of the solute, the size and shape of the particles to be prepared, and the cost of equipment, etc., to choose a suitable method.

Micronization equipment Cost and supercritical fluid micronization equipment price

Our supercritical fluid micronization equipment price is lower than our peers’, and our waterless dyeing machine is high quality, we have our own manufacturing factory, all products are factory price, there is absolutely no middleman markup, we accept both small batch scale customer and large industrial batch scale wholesale micronization machines and supercritical CO2 fluid micronization machine for sale online

About Supercritical fluid micronization equipment

Supercritical CO2 fluid micronization equipment is a specialized system used in various industries for the micronization or reduction of particle sizes using supercritical carbon dioxide as the fluid medium. This equipment utilizes the unique properties of supercritical CO2 to achieve precise and efficient particle size reduction, making it an essential tool in applications such as pharmaceuticals, food processing, cosmetics, and more.

Working Principle

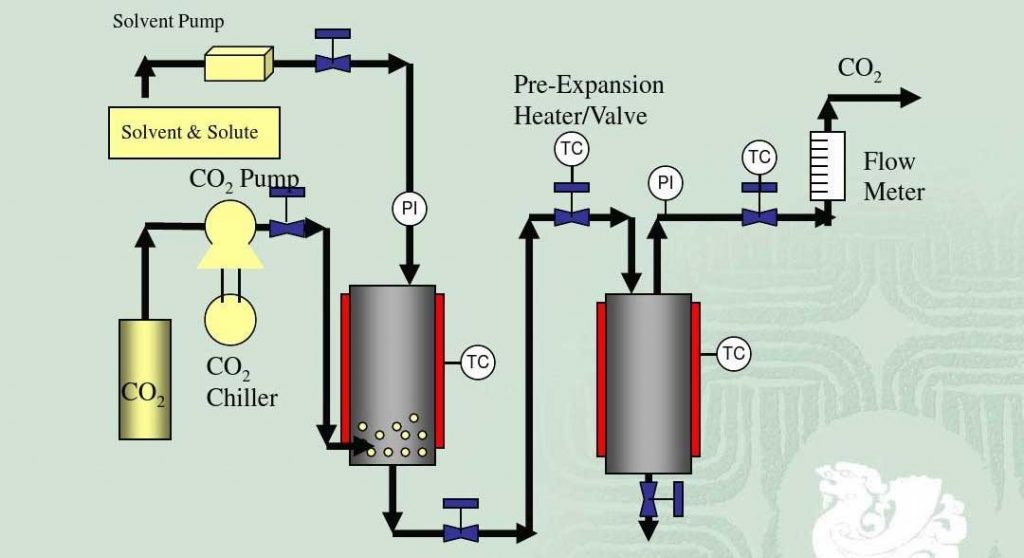

Supercritical CO2 fluid micronization equipment operates based on the principles of supercritical fluid technology. Supercritical fluids, such as CO2, exhibit properties of both gases and liquids when exposed to specific temperature and pressure conditions. In the case of supercritical CO2, it is brought to a temperature and pressure beyond its critical point, resulting in a supercritical state where it displays excellent solvating power.

The process starts by feeding the material to be micronized into a high-pressure vessel or chamber. The supercritical CO2 is then introduced into the chamber, creating a supercritical fluid environment. As the supercritical CO2 interacts with the material, it penetrates the particles and solubilizes the target compounds. The pressure is then rapidly reduced, causing the supercritical CO2 to transition back to a gas state and leaving behind micronized particles.

Benefits of Supercritical CO2 Fluid Micronization Equipment

Precise Particle Size Control: Supercritical CO2 fluid micronization allows for precise control over the particle size distribution. By adjusting the operating parameters such as pressure, temperature, and flow rate, manufacturers can achieve the desired particle size range for their specific application.

Gentle Processing Conditions: Unlike traditional micronization methods that utilize mechanical force or high temperatures, supercritical CO2 fluid micronization operates under relatively mild conditions. This gentle processing helps preserve the integrity of heat-sensitive or thermally unstable compounds, making it suitable for applications in the pharmaceutical and food industries.

Solvent-Free Operation: Supercritical CO2 fluid micronization is a solvent-free process. Carbon dioxide is widely recognized as a safe and environmentally friendly solvent, as it is non-toxic, non-flammable, and readily available. Its use eliminates the need for potentially harmful solvents, ensuring product safety and reducing environmental impact.

Versatile Application Range: Supercritical CO2 fluid micronization equipment can be applied to various materials, including pharmaceutical compounds, herbal extracts, food ingredients, pigments, and more. This versatility makes it a valuable tool for different industries seeking to enhance the properties and performance of their products.

Enhanced Bioavailability: Micronization of pharmaceutical compounds using supercritical CO2 can significantly improve their bioavailability. The reduced particle size increases the surface area, facilitating better dissolution and absorption in the body, which can lead to improved therapeutic efficacy.

Conclusion

Supercritical CO2 fluid micronization equipment plays a vital role in achieving precise particle size reduction for various materials in industries such as pharmaceuticals, food processing, cosmetics, and more. Its ability to provide controlled particle size distribution, operate under gentle processing conditions, and offer solvent-free operation makes it an attractive choice for manufacturers looking to enhance product performance and quality. As technology continues to advance, supercritical CO2 fluid micronization equipment is expected to further contribute to the development of innovative and efficient processes in various fields.