Ganoderma lucidum, commonly known as reishi mushroom, is well-known for its medicinal properties. Ergosterol is an important bioactive compound found in Ganoderma lucidum mycelium. Supercritical CO2 extraction is an effective method for extracting ergosterol from Ganoderma lucidum mycelium due to its efficiency and preservation of active ingredients. In this article, we will discuss the supercritical CO2 extraction method for ergosterol, its benefits, and the optimal extraction conditions.

CO2 Extraction Process for Ergosterol

Supercritical CO2 extraction is a method that uses carbon dioxide (CO2) at high pressure and low temperature to extract desired compounds from Ganoderma lucidum mycelium. Ergosterol is extracted from Ganoderma lucidum mycelium under supercritical CO2 conditions. Subsequently, a co-solvent, commonly ethanol, which increases the solubility of ergosterol in the supercritical CO2 is added. This improves the yield of ergosterol in the final extract.

The following table shows the optimal process parameters for supercritical CO2 extraction of ergosterol:

| Process Parameter | Value |

|---|---|

| Temperature | 40-50°C |

| Pressure | 250-300 bar |

| CO2 Flow Rate | 15-25 kg/h |

| Extraction Time | 2-3 hours |

| Yield | 2.5-3% |

The optimal temperature for the supercritical CO2 extraction of ergosterol is between 40-50°C, and the pressure range should be between 250-300 bar. CO2 flow rate should be set between 15-25 kg/h, and the extraction time should be between 2-3 hours. These parameters can help achieve a yield of 2.5-3% of ergosterol in Ganoderma lucidum mycelium.

Advantages of Supercritical CO2 Extraction of Ergosterol

Supercritical CO2 extraction of ergosterol offers several advantages over conventional extraction methods. Firstly, it is a safe, non-toxic, and environmentally friendly technique that does not require the use of harmful solvents. Secondly, this method has a high selectivity for ergosterol, meaning that the extract is rich in bioactive compounds. Finally, the final product is of high purity and free from any solvent residues, making it ideal for use in the pharmaceutical and nutraceutical industries.

Ganoderma lucidum

Ganoderma lucidum belongs to the basidiomycetes, the porous fungi, and the noble fungi with high medicinal value.

It has the functions of anti-inflammatory, diuretic, stomach invigorating, preventing arteriosclerosis, anti-tumor, anti-aging and improving immunity.

Ergosterol

The research shows that there are many functional substances in Ganoderma lucidum, such as polysaccharides, triterpenoids, Ganoderma acid, ergosterol, and so on. The content of ergosterol in Ganoderma lucidum is high, It can reach more than 0.2%, and the content of ergosterol in Ganoderma lucidum can reach UV irradiation. Ergosterol can be converted into a VD2 precursor, it is the main raw material for the production of progesterone, hydrocortisone, VD2, etc., with large market demand.

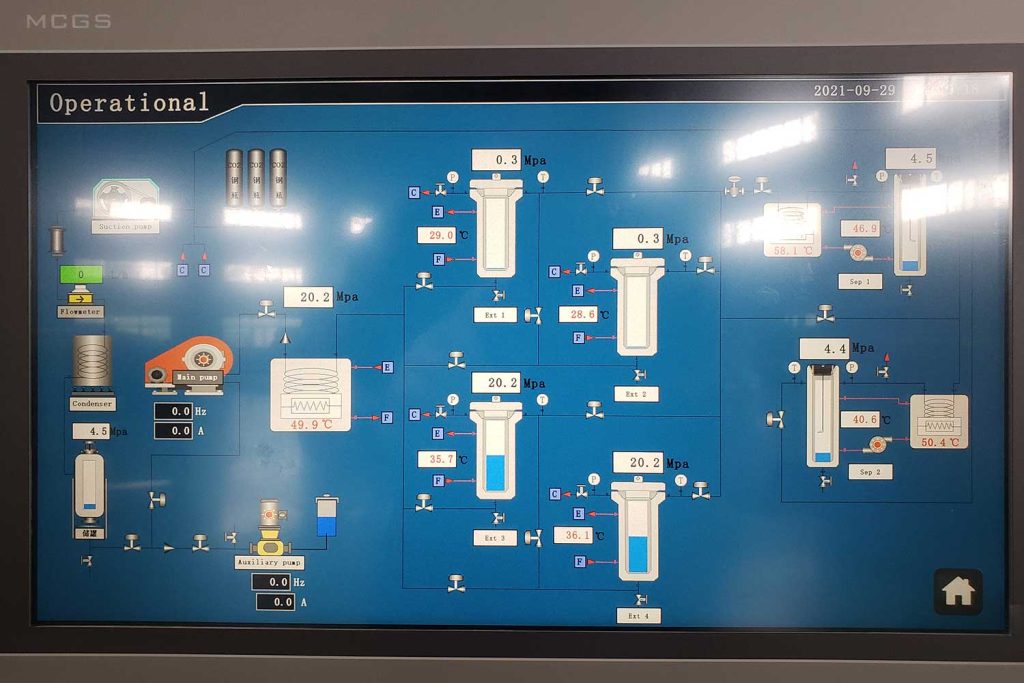

CO2 Extraction process of ergosterol from Ganoderma lucidum

- Extraction pressure: 20 MPa

- Extraction temperature: 50°C

- CO2 flow: 2.5 L / min

- Extraction time: 120 min

CO2 Extraction method

Fermentation

The production of Ganoderma lucidum mycelium by deep fermentation is characterized by time-saving, labor-saving, environmental protection, and easy control.

Supercritical CO2 fluid extraction is based on the relationship between the solubility of supercritical fluid and its density, that is, the influence of pressure and temperature on the solubility of supercritical fluid. In the supercritical state, the supercritical fluid is contacted with the substance to be separated, so that it can selectively extract the components of polarity, boiling point, and molecular weight successively, which has the characteristics of time-saving, labor-saving, environmental protection, and good separation effect.

Based on the deep fermentation of Ganoderma lucidum fungus, the content of ergosterol in Ganoderma lucidum mycelium was extracted by CO2 supercritical, and the extraction conditions were optimized.

CO2 extraction

After deep fermentation of Ganoderma lucidum fungus for 120 hours, the mycelium and fermentation liquid is separated by centrifugation, the mycelium is taken, dried to constant weight in a constant temperature oven at 60 ℃, cooled to normal temperature in the dryer, weighed, mashed, sieved, 100 g of experimental sample is taken and put into the reaction kettle, CO2 gas is opened, at the same time, the temperature of extraction kettle, separation kettle I and separation kettle II is adjusted to the set temperature, and then pressurized to the set pressure. Adjust the flow of CO2, and make the supercritical CO2 fluid carry out the extraction cycle under the set pressure and temperature.

When the CO2 extraction time reaches the test set, receive the extraction liquid from the separation kettle I and the outlet of the separation kettle, combine the extraction liquid of the separation kettle I and the separation kettle II, and fix the volume to 500ml, then obtain the supercritical CO2 extraction liquid sample of Ganoderma lucidum fungus deep fermentation bacteria, for standby.

extraction pressure, extraction temperature, and CO2 flow rate

In the process of extracting ergosterol from Ganoderma lucidum mycelium by supercritical CO2, single-factor experiments show that the extraction pressure, extraction temperature, and CO2 flow rate have different effects on the extraction amount of ergosterol.

L934 orthogonal experiment optimizes the extraction conditions. The results show that the extraction pressure and extraction temperature have significant effects, while the CO2 flow rate has no significant effects.

Cleaning a CO2 extraction machine

The appropriate combination of the three factors A2b3c3, i.e. extraction pressure 20 MPa, extraction temperature 50 ℃, CO2 flow rate 2.5 L / min, the extraction amount of ergosterol in this combination is 1.1362 mg / g, which is higher than that in the orthogonal combination.

Cleaning a CO2 extraction machine involves several steps to ensure the main section and water system are properly cleaned. Here is the correct procedure:

Cleaning the CO2 extraction machine main section

Begin by recovering the CO2 from the system into the CO2 storage tank. Close the inlet and outlet valves of the CO2 storage tank, as well as the quick-opening device, blowdown valve, and emptying valve of the extraction kettle.

For the blowdown valve and drain valve of the primary and secondary separation kettle, open the regulating valves J65 and J66 and close the drain valve of the condenser.

Inject the cleaning agent into the main section of the CO2 extraction machine until liquid overflow occurs at the high discharge outlet.

Allow the cleaning agent to soak in the main section for 30 minutes at a high temperature.

Open the drain valves at the bottom of the extraction kettle and the separation kettle respectively, and slowly discharge the cleaning agent.

Use the cleaning agent pump to circulate and wash the main section and each container.

Drain the cleaning agent and rinse the main section and each container with clean water.

Ensure all water is drained from the main section and containers, and use dry compressed air to dry them. The chlorine ion content of the cleaning agent or clean water should not exceed 25mg/L.

Cleaning the CO2 extraction machine’s cold and hot water system

Close or open the corresponding valves for the cold and hot water system.

Replace the hot water tank (C304) and cold water tank (C305) with fresh clean water.

Start the cold water circulation pump and hot water circulation pump.

Flush the pipes and equipment with clean water for approximately 10 minutes to remove any water from the system.

Additional considerations

Depending on the extraction products, a more specific cleaning process may be required. Follow the detailed cleaning instructions provided by the manufacturer or develop a cleaning process suitable for the specific extraction products.

Ensure the chlorine ion content of the cleaning agent or clean water used during the cleaning process does not exceed 25mg/L.

Remember to consult the manufacturer’s instructions and guidelines specific to your CO2 extraction machine for accurate and detailed cleaning instructions.

Conclusion

Supercritical CO2 extraction is an efficient and effective method for extracting ergosterol from Ganoderma lucidum mycelium. It offers several benefits over traditional methods, including its safety, environmental friendliness, and high selectivity. Optimal extraction parameters, including temperature, pressure, CO2 flow rate, extraction duration, and yield, are critical for achieving high-quality ergosterol extracts. With these parameters, high-quality ergosterol extract from Ganoderma lucidum mycelium can be produced sustainably, meeting the demands of the nutraceutical and pharmaceutical industries.