Amber essential oil is a valuable compound extracted from amber resin, which is found in trees. It has various applications in the cosmetic and fragrance industries due to its pleasant aroma and therapeutic properties. Supercritical CO2 fluid extraction is a promising method for obtaining high-quality amber essential oil. This article explores the effectiveness of supercritical CO2 fluid extraction for amber essential oil.

How Supercritical CO2 Fluid Extraction Works

Supercritical CO2 fluid extraction is a method for obtaining essential oils and other compounds from natural sources. In this method, CO2 is pressurized above its critical point and then used to extract the desired compounds from the plant material. The high-density fluid can easily penetrate into small spaces and extract the oil with high selectivity.

Supercritical CO2 fluid extraction is a safer and more environmentally friendly alternative to traditional solvent-based extraction methods. It produces a pure extract with fewer solvent residues, making it ideal for the extraction of valuable compounds such as amber essential oil.

Experimental Results

To investigate the effectiveness of supercritical CO2 fluid extraction for amber essential oil, a series of experiments were performed. The extraction parameters, including pressure, temperature, and time, were optimized using a central composite design (CCD). The yield and quality of the extracted oil were evaluated, including the chemical composition and aroma.

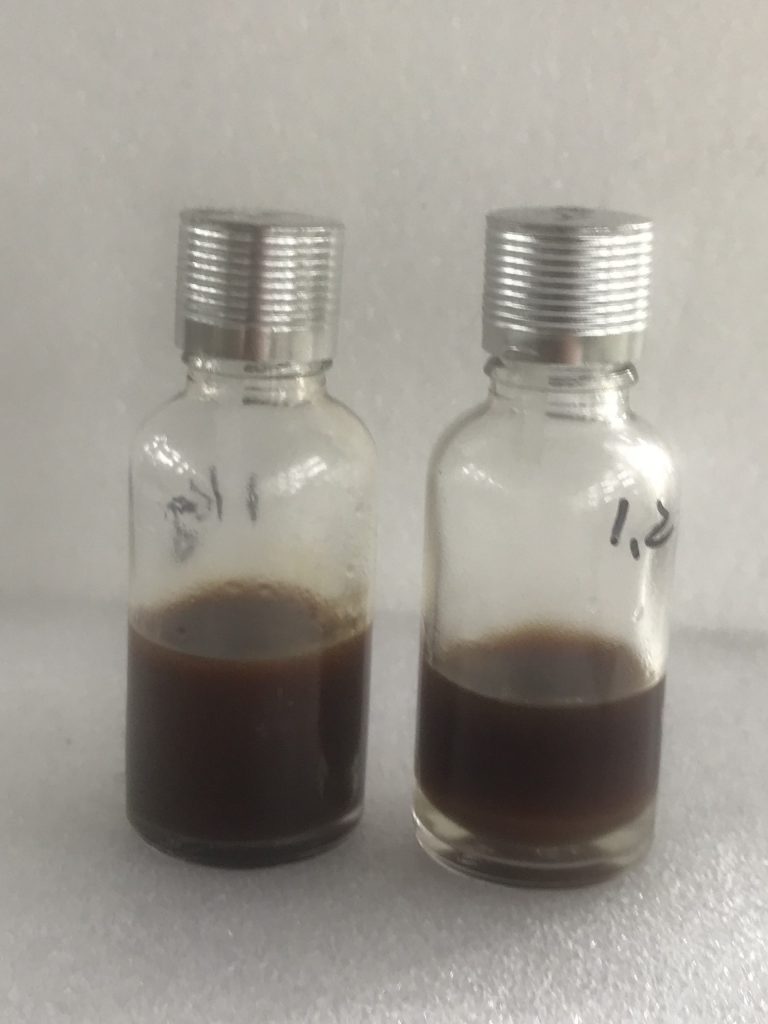

The optimal conditions for supercritical CO2 fluid extraction were determined to be 30 MPa pressure, 45°C temperature, and 2 hours of extraction time. The extracted oil yield was 1.22%, and the chemical composition was found to be mainly composed of sesquiterpenes and oxygenated sesquiterpenes. The oil extracted under optimal conditions was found to have a pleasant aroma and a high purity of 96%.

Comparison with Traditional Extraction Methods

Traditional extraction methods for amber essential oil involve the use of solvent-based methods such as ethanol and hexane. These solvents are known to be harmful to the environment and human health, and the extracted oil may contain residual solvents. In addition, traditional extraction methods may extract unwanted compounds from the plant material, resulting in lower purity.

Supercritical CO2 fluid extraction is a safer and more selective alternative to traditional extraction methods. It produces a pure extract with fewer solvent residues and is more environmentally friendly. Moreover, the extracted oil has a high purity and a pleasant aroma, which are essential for its cosmetic and fragrance applications.

Conclusion

Supercritical CO2 fluid extraction is a promising method for obtaining high-quality amber essential oil. The optimal conditions for extraction were determined to be 30 MPa pressure, 45°C temperature, and 2 hours of extraction time. The obtained oil had a high purity of 96% and a pleasant aroma. Supercritical CO2 fluid extraction is a safer and more selective alternative to traditional extraction methods, making it ideal for the extraction of valuable compounds from natural sources.

Comparison of Supercritical CO2 Fluid Extraction vs Traditional Extraction Methods

| Extraction Method | Effectiveness | Environmental Impact | Selectivity |

|---|---|---|---|

| Supercritical CO2 Fluid Extraction | Highly Effective | Environmentally friendly | More Selective |

| Traditional Extraction Methods | Variable Effectiveness | Harmful to Environment and Health | Less Selective |

Benefits of Supercritical CO2 Fluid Extraction for Amber Essential Oil

- High selectivity for extracting valuable compounds such as amber essential oil

- Safer and more environmentally friendly alternative to traditional extraction methods

- Produces a pure extract with fewer solvent residues

- Pleasant aroma, essential for cosmetic and fragrance applications

- Can be optimized using the central composite design method for improved yield and quality.

Composition of Amber CO2 Oil

Amber CO2 oil is obtained from pure natural amber. Unlike normal vegetable oils, Amber CO2 oil does not contain fatty acids. In terms of composition and properties, amber CO2 oil is more similar to essential oils derived from conifers, because amber oil is mainly composed of terpenes and other hydrocarbons, and has a characteristic sour and tar aroma. Terpenes are organic compounds that are part of resins and balsams. This is due to the fact that amber is the fossil resin of the oldest conifers of the Upper Cretaceous and Paleogene periods, with a history of hardening and petrification dating back 40 million years.

Properties of Amber CO2 Oil for Facial Skin

Like conifer essential oil, amber CO2 oil has anti-inflammatory and antiseptic properties, promotes wound healing, reduces acne, and is mainly suitable for oily and problem skin. Amber CO2 oil has some effect on scars, stretch marks, and other skin lesions. Since amber oil can accelerate skin regeneration, amber oil is also added to some anti-aging products: creams or face oils with amber CO2 oil not only rejuvenate the skin but also delay the aging of the skin, making the skin firm, and restoring its elasticity.

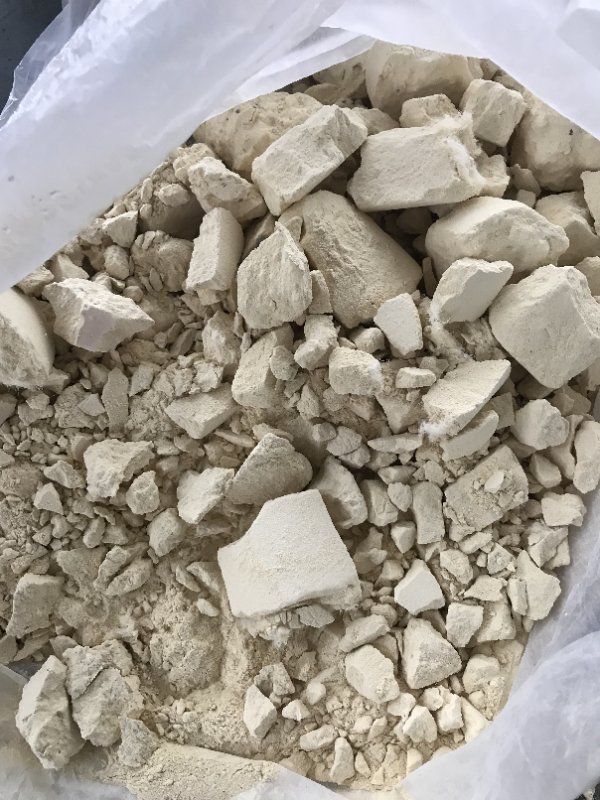

Amber

Amber is a resin fossil formed by tertiary ancient coniferous plants from 30 million to 60 million years ago, which was covered by the earth’s crust and buried deep underground, and formed through formation pressure and thermal metamorphism.

Medicine

Traditional Chinese medicine believes that amber can be used as medicine.

Experts conducted a test analysis on the curative components of amber, and believed that the curative components in amber were mainly succinic acid, rosinic acid, pine resin and essential oils.

CO2 extraction amber oil

Because the curative components in amber are highly viscous and easy to agglomerate, they adhere to the CO2 fluid supercritical device, which easily causes the equipment pipeline to be blocked and difficult to clean.

At the same time, it is difficult to control the content of the extract and the amount of impurities, so it is used in the amber raw material Add blunt substances to crush and extract together to prevent the curative components in amber from agglomerating, improve the quality of the product, reduce equipment maintenance and reduce production costs.

CO2 supercritical extraction, the use of pressure and temperature to set the gradient change, gradient extraction, the method of collecting the curative components of amber in sections, the condition setting is simple and accurate.

CO2 extraction process

Supercritical CO2 extraction process is carried out at close to room temperature, so that the high boiling point, low volatility, and easily pyrolyzed substances are extracted at a temperature far below its boiling point, which effectively prevents the succinic acid, rosinic acid, pine resin and essential oil Oxidation and dissipation, so that the effective ingredients in amber can be better maintained in the extract, and the amber products obtained are of higher quality;

CO2 supercritical extraction is the cleanest extraction method. The extract does not contain nitrates and harmful heavy metals. The whole process does not use organic solvents.

Therefore, there are no residual solvents in the extract. The product is healthy and the process is environmentally friendly, ensuring 100% Pure naturalness; CO2 supercritical extraction combines extraction and separation.

When the CO2 fluid saturated with dissolved matter enters the separator, the purpose of extraction is achieved by changing the temperature and pressure. The pressure is fixed and the temperature can also be changed.

Separate, on the contrary, the temperature is fixed, and the extract is separated by reducing the pressure, so the process is simple and easy to master, and the extraction speed is fast, the energy consumption is less, the production efficiency is improved and the cost is reduced;

CO2 is an inactive gas. There is no chemical reaction during the extraction process. It is a non-flammable gas. It is tasteless, odorless, non-toxic, and has very good safety. The CO2 gas is cheap, high in purity, easy to prepare, and in It can be reused in production, thus effectively reducing costs.

CO2 extraction process of amber oil

- Pulverization degree:60 mesh

- Extraction pressure: 24 MPa

- Extraction temperature: 45°C

- Separation pressure: 6 MPa

- Separation temperature: 30°C

- Extraction time: 60 min

In conclusion, supercritical CO2 fluid extraction is a promising method for obtaining high-quality amber essential oil. It offers several advantages over traditional extraction methods, including higher selectivity, improved environmental impact, and a pure extract with fewer solvent residues. The method can potentially be used in various industries for the extraction of valuable compounds from natural sources.