Rose CO2 Supercritical Extract is a bit thicker and more absolute because the CO2 extraction process is able to extract more of the heavier aromatic molecules, natural plant waxes and resins than can the process of steam distillation.

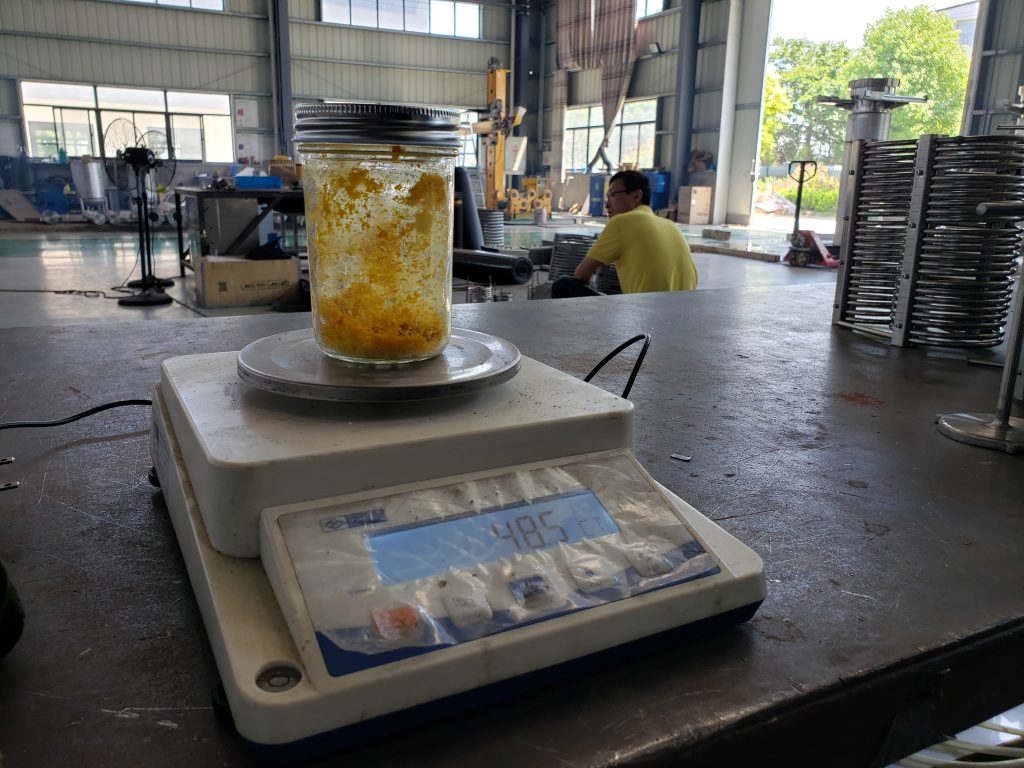

Rose co2 extract

Rose essential oil contains a large amount of citronellol, geraniol, nerol, and other compounds. It has long been one of the popular floral essential oils in the international food industry market, mainly used in beverages, candy, ice cream, seasonings, In health food.

The rose essential oil can be used to produce high-quality perfumes and high-quality cosmetics. The market is expensive and the demand is huge; however, the existing technology has a low extraction efficiency of rose essential oil, complex processes, and polluted the environment. There is an urgent need to develop a new rose The extraction process of flower essential oil transforms roses into a new value-added development direction.

Rose co2 Oil

Rose CO2 Supercritical Extract is a bit thicker and more absolute because the CO2 extraction process is able to extract more of the heavier aromatic molecules, natural plant waxes, and resins than can the process of steam distillation.

Aromatically, rose CO2 extract offers a beautiful, floral aroma that is more complete and more closely represents the natural fragrance of fresh roses (Rosa damascene).

This is because the low-temperature CO2 extraction preserves the terpenes better of rose.

The terpenes of rose extract

Terpenes are aromatic oils that are found in a variety of organisms, including plants such as roses. More than 100 different terpenes have been found in some plants, and each different plant species has a unique terpene composition.

Terpenes are formed in the trichomes of plants and are responsible for making the plant’s aroma and taste. The development of terpenes within plants is thought to be an evolutionary adaptation to attract pollinators and repel predators.

However, this is not their only function, as scientists believe that terpenes can have a variety of physiological effects in humans. Since terpenes are hydrocarbons with variable structures, these effects are often related to their molecular “backbone”. The units in its molecular structure are acted upon by various enzymes, resulting in oxidation and increased function.

For this reason, it is not surprising that terpenes are the main constituents of essential oils. These aromatic oils are responsible for regeneration, oxidation, defense mechanisms, and immunity of plants. Furthermore, they have been extracted from plants by humans and used for medicinal purposes for thousands of years.

Guide to the CO2 extraction method of rose oil

The combination of supercritical extraction and molecular distillation not only has a low operating temperature and a short heating time, but it can avoid the oxidation and rancidity of grease caused by high temperature, and the separation degree and product yield are high. Molecular distillation can also reduce rose oil The acid value does not need to be centrifuged, which reduces costs.

Remove impurities from fresh roses, put them in vacuum freeze-drying equipment for 20-30 hours, then take them out, put them in crushing equipment, crush and sieve, to prepare 50-60 mesh rose crushed material, and set aside;

Set the pressure in the co2 extractor to 20Mpa and the temperature to 40°C. The mixed fluid of the extracted CO2 and rose essential oil is input into the separator for decompression separation. The pressure in the separator is 6Mpa and the temperature is 37°C.

After the CO2 is liquefied by the liquefier, it is directly returned to the storage tank at 26°C for the next round of extraction and separation cycle. Each round of extraction and separation time is 1.5 hours. After separation, the primary rose oil is prepared and reserved;

Molecular distillation

Primary rose flower oil is added to the molecular distiller, the vacuum degree in the molecular distiller is set to 1.0-2.0Pa, the temperature is 60-80°C, and the rotating brush speed in the molecular distiller is 120r/min until The primary rose oil is completely collected by the heavy-phase collection tank and the light-phase collection tank, and the rose-phase crude oil is collected in the heavy phase collection tank and is used;

Add rose oil to the molecular distiller again, reset the vacuum degree in the molecular distiller to 1.0-2.0Pa, the temperature to 60-80°C, and the rotating brush speed in the molecular distiller to 120r/min Until rose oil is completely collected by heavy phase collection tank and light phase collection tank, and rose oil is collected in the heavy phase collection tank.

CO2 Extraction Process

- Extraction pressure: 20 MPa

- Extraction temperature: 40°C

- Extraction time: 90 min

- Separation kettle Ⅰ pressure: 6 MPa

- Separation kettle Ⅰ temperature: 37°C