What is a cold press?

The cold-press method of extraction received its name from the German words 'kalt geschlagen'. The word mentioned means ‘cold pummeling’. It is believed that it refers to the intensive pressure that seeds and fruits bear.

The cold press method is a type of mechanical extraction that extracts oil from oilseeds, peels, or fruit of the plant. It is also known as mechanical separation or expression or expeller pressing. The process is termed a 'cold' press because no heat is involved. Naturally, oilseeds can be just crushed to extract oil. Sesame seeds, orange, lemon, coconut, and groundnut are some raw materials from which oil can be retrieved by just pressing.

Cold press process of Extraction

The cold-pressed process is a mechanical separation process also referred to as solid-liquid phase separation, used for oil extraction with oil content below 20%.

Pressure is an important parameter that is applied for extraction.

In earlier days, cold-pressed oils were extracted by hand and made use of specialized sponges that helped to absorb plants’ oil and liquid, modern cold press machines utilize centrifugal force for the separation of oil from plant liquid.

What is CO2 extraction?

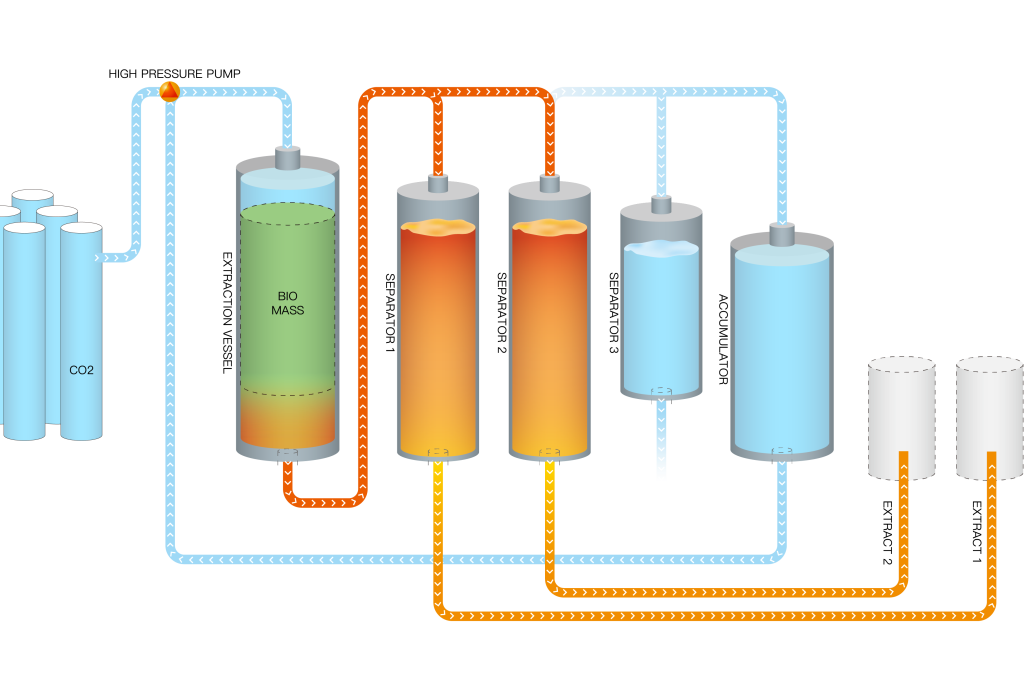

Supercritical fluid extraction (SFE) is the process of separating one component (the extractant) from another (the matrix) using supercritical co2 fluids as the extracting solvent. CO2 is a natural and environmentally-friendly solvent that has advantages over synthetic and harmful media such as n-hexane when it comes to sustainability. Among several supercritical fluids (abbreviated SCF) technologies, the earliest developed, most researched, and industrialized product technology is undoubtedly the supercritical fluid extraction (abbreviated SFE) technology.

The supercritical CO2 extraction process is used particularly in the food, beverage, cosmetics, and pharmaceutical industry for extracting natural substances, aromas, fats, oils, waxes, polymers, enzymes, and colorants in their supercritical physical state. CO2 extraction methods are often used in the extraction of plant essential oils.

PRINCIPLE

The supercritical co2 extraction process uses a supercritical co2 fluid as the separation medium (extractant). It uses the fluid to have a highly enhanced dissolving ability in a supercritical state to achieve effective extraction of certain components (solutes) in the raw material and then pass the temperature. The continuous adjustment of the pressure can reduce the density of the extractant, that is, reduce its solubility to the solute, to achieve high-efficiency separation of specific components in the raw material.

ADVANTAGES

Because supercritical co2 fluid has excellent mass transfer characteristics of gas and solvation ability equivalent to liquid solvents, the supercritical co2 extraction process using it as a separation medium is considered to integrate the two-unit operations of distillation and liquid-liquid extraction to a certain extent. The advantages of this form are a unique separation technology. The basis of the theory is the phase equilibrium relationship of the fluid mixture in the supercritical state, which operates in the mass transfer process.

- Purer: CO2 extracted material is free of residual solvents. Nothing is left behind once the extraction is over since the carbon dioxide bubbles away, leaving no trace in the end product.

- Safer: Comparing CO2 cannabis extraction to butane or propane? Don’t forget to include the facility costs for processing with compressed flammable gas.

CO2 extraction vs cold pressed

Okay, so if cold pressed CBD is so great why do most companies use co2 extraction? Whilst cold pressed hemp produces a higher quality CBD oil, it also results in a lower yield. There is no doubt that CO2 is the optimization when it comes to extracting essential oils with high economic added value. Supercritical CO2 extraction ensures the freshness of flavour, colour & odor – as well as quality, especially when used to create oils which are highly susceptible to oxidation & rancidity. While other extraction methods are competitively comparable, they cannot all be rated equally. And how oils are manufactured is essential to how the product will hold up – both on the shelf and on the market.

Why CO2 extraction is optimization?

Because oxygen-free environments and low temperatures are particularly important, especially for fragile ingredients such as Cannabis or Sea Buckthorn Seeds.

Why lack of oxygen can make sense

In contrast to cold pressing, with CO2 extraction no oxygen comes into contact with the plant material to be processed. In this way, the sensitive natural substances remain protected from oxidation, are more durable, and cannot become rancid so quickly.

It maximizes the ingredient benefits

The CO2-extracted oils are considered more fragrant and richer.

By keeping temperatures low and extracting all the ‘active’ components, we’re able to preserve and protect the complete botanical, active substances, and terpenes of the CBD.

Another example, a direct comparison has shown that the proportion of phytosterols in CO2 extraction is higher than in cold pressing.

It is precisely the phytosterols obtained from oil-containing plants that balance the skin\’s moisture balance and are therefore often used for dry skin. They have an anti-itch and anti-inflammatory effect.

Low-temperature extraction

Whilst some heat is generated from mechanical friction, this is significantly lower than other methods including popular CO2 extraction. Many delicate plant phytonutrients are temperature sensitive and are often degraded or depleted using higher-temperature extraction methods. Keeping temperatures low results in the extracted oil being far richer in these sensitive nutrients, contributing to the entourage effect and producing greater efficacy of the end product.

Cold-pressed hemp oil is also considered to have a better flavor and aroma, which is down to the higher concentration of terpenes and monoterpenes found within the extract.

Whilst cold-pressed hemp produces a higher quality CBD oil, it also results in a lower yield. Higher temperatures reduce overall nutrient content but the heat makes the plant matter softer and easier to break down, resulting in higher yields and ultimately higher profits.

It creates a purer product

CO2 extraction also leaves absolutely no solvent residues, so the final oil is impeccably pure. This includes the incredible natural color and smell. You only have to see how orange, concentrated, and herbaceously-scented Sea Buckthorn Seeds bio regenerate is to witness CO2 extracts at their optimization.

It’s better for the environment

Last but by no means least, the low temperature and lack of waste streams/emissions make it an extremely environmentally-friendly process.

The primary benefits of supercritical CO2 extraction

- Limited rancidity – no pre-exposure to oxygen means reduced chances of spoilage, so the product and its benefits keep for as long as possible

- Stability – fragile oils are of higher quality when extracted with low or no heat

- Selective process control – obtaining constituents that hold the optimization healing properties, adding to its effectiveness

- Environmentally sound – using carbon dioxide (a natural byproduct of human existence) for pharmacological & medical practices is a completely natural and safe method for oil extraction

The advantages of the co2 extraction process to conventional cold-pressing

- The lower temperature of operation: heat-sensitive components remain intact;

- Exclusion of oxygen: oxidation-sensitive components remain intact;

- Higher selectivity and higher mass transfer which leads to a higher yield and a longer shelf-life;

- Cleaner process both in terms of environmental impact and yield;

- Longer shelf-life of the product compared to conventional extraction methods; and a

- More good flavor and scent compared to conventional products.

Disadvantages of the supercritical co2 extraction process

- Higher costs and technological requirements compared to a conventional extraction of maceration;

- Usually a very intense color of the extract; and

- CO2 extracts generally cost more.

CO2 extraction and cold-pressed for cannabis extraction

Both CO2 extraction and cold-pressed methods are used for cannabis extraction and offer different benefits and drawbacks.

CO2 extraction is a popular method for cannabis extraction because it can produce highly concentrated and pure oil. It uses CO2 gas in a high-pressure system to extract cannabinoids, terpenes, and other compounds from the plant material. It requires specialized equipment, which can make it expensive, but it’s also non-toxic and leaves no harmful residues in the final product.

On the other hand, cold-pressed extraction involves crushing the plant material to release the oils, which are typically less concentrated than those produced by CO2 extraction. Cold-pressed methods may produce more natural and flavorful oil, and it is a simple, affordable, and more efficient process, especially for small-batch production.

When it comes to cannabis extraction, the decision on which method is better is entirely up to the intended use and the desired outcome. CO2 extraction is preferred for extracting high-quality oils that are potent, concentrated, safe, and can be used in medical research studies. Meanwhile, the cold-pressed extraction method is preferred for small batch uses, home usage, or for producing a therapeutic-type oil with a rich flavor that is suitable for topical use.

In conclusion, there is no definitive answer to which method is truly better. It depends on one’s goals, preferences, and intended use. Both methods offer benefits and drawbacks and produce significantly different outcomes in terms of purity, potency, and concentration.

Example comparison of co2 extraction vs cold pressed

We provide the extraction table of essential oils extracted by two extraction methods and the extraction experiment of walnut oil for comparison:

Walnut Oil Extraction: CO2 Extraction vs Cold Pressing

To compare the oxidative stability of cold-pressed and supercritical CO2-extracted walnut oil under dark and light conditions, we measured the peroxide value of walnut oil and conducted the sensory evaluation.

Cold pressing

Cold pressing is a traditional process for oil production. Because this method is relatively inefficient, labor-intensive, and low in oil yield, cold pressing is rarely used for the oil production of bulk oils. However, because this method is a physical method, it is pressurized without heating up and does not affect oil and vegetable protein, so it is suitable for the preparation of special oil such as walnut oil.

CO2 extraction

The supercritical CO2 extraction process is currently recognized as one of the most ideal separation technologies. It is an advanced technology that utilizes CO2 in a supercritical state under high pressure to extract and separate various useful substances. Because CO2 is non-toxic, and non-polluting and the separation of CO2 and oil is relatively simple, and the operating temperature is relatively low, it is also suitable for the preparation of walnut oil.

Materials and Equipment

Walnut kernels: from Changzhi, Shanxi, fresh and dried;

Supercritical CO2 extraction machine: L-02 (1 lb co2 extractor);

Fast hydraulic oil press, type 6YY-190;

Constant temperature incubator: HPX-9082;

Light meter: TES-1332 type.

Main reagents: chloroform, acetic acid, potassium iodide, sodium thiosulfate, 0.5% starch solution.

Method and process

Supercritical CO2 Extraction Process

Supercritical CO2 extraction of walnut oil: pulverize the walnut kernels to about 30 mesh, put them into the extraction kettle, adjust the extraction kettle pressure to 32MPa, the extraction temperature to 40℃, and extract for 3.5h; the pressure of the separation kettle I am 12MPa, the temperature is 40℃; the separation The pressure of the kettle II is 6.5MPa, the temperature is 40℃; the flow rate of CO2 is 10kg/h. Collect 400 ml of extracted oil.

Cold-pressed walnut oil

Cold pressing to make walnut oil: wrap the walnut kernels with cloth and put them into the barrel, adjust the pressure to 60MPa for cold pressing, the walnut oil slowly flows out, collect 400 ml, and centrifuge the walnut oil for 10 minutes at a speed of 6000 r/min, Remove impurities.

The comparative experiment of CO2 extraction and cold pressing of walnut oil

Referring to the Schaal oven method, create the conditions for the accelerated test: in a dark incubator, adjust the temperature to 60°C and the relative humidity to 70%;

In a lighted incubator, adjust the temperature to 40°C, the relative humidity to 70%, and the illumination to 500lx. Measure 6 parts of 50ml cold-pressed walnut oil into 100ml conical flasks with stoppers, tighten the caps, and put three of them in a dark incubator, and the other three in a light incubator In the same way, measure 6 parts of 50ml supercritical CO2 extracted walnut oil and put them into 100ml conical flasks with stopper respectively, put three of them into a dark incubator, and the other three into a light incubator middle. The samples were placed in an incubator for 20 d. The peroxide value was measured every 5 d. The average value of the peroxide value of three identical samples in the same incubator was calculated.

Results and analysis

Determination of Peroxidation Value of Walnut Oil

According to the method specified in GB/T5009.37-1996, the peroxide value (PV) of cold-pressed walnut oil and supercritical CO2 extracted walnut oil under dark and light conditions was determined.

- Under the conditions of a temperature of 60℃, relative humidity of 70%, and darkness, the peroxide value of walnut oil extracted by supercritical CO2 is higher than that of cold-pressed walnut oil, which indicates that the oxidation stability of walnut oil extracted by supercritical CO2 is higher than that of cold-pressed walnut oil. low oil.

- Under the conditions of a temperature of 40℃, relative humidity of 70%, and illumination of 500lx, the peroxide value of walnut oil prepared by cold pressing is higher than that of walnut oil extracted by supercritical CO2, which shows that the stability ratio of cold-pressed walnut oil under this condition is higher than that of walnut oil extracted by supercritical CO2. The stability of walnut oil extracted by supercritical CO2 is low.

CO2 extraction vs cold pressed

The purpose of the two storage conditions in the test is different: the temperature of 60°C, the relative humidity of 70%, and the absence of light are to measure the properties of walnut oil auto-oxidation; the temperature of 40°C, the relative humidity of 70%, and the light intensity of 500lx. It is to measure the properties of walnut oil photo-oxidation. This is of great significance for guiding the packaging method of walnut oil: cold-pressed oil has poor photo-oxidative stability, so it is optimization to use dark packaging materials to reduce the influence of light; walnut oil extracted by supercritical CO2 fluid is relatively stable due to photo-oxidation. Strong, can be packaged with transparent material.

Dark conditions

The stability of the walnut oil extracted by supercritical CO2 was poor in the absence of light, which may be due to its relatively low VE content in it. VE is a natural antioxidant. Although the temperature in the supercritical CO2 fluid extraction process is only a dozen degrees Celsius higher than that in the cold pressing process, the duration is longer, dozens of times that of the cold pressing process, which may affect the anti-oxidant properties of VE. Oxidation effect.

Light conditions

Under light conditions, the presence of chlorophyll reduces the photooxidative stability of the oil. Cold-pressed oils are less stable, possibly because of their higher chlorophyll content. Chlorophyll is easily decomposed when the temperature increases and lasts for a long time. The higher temperature in the supercritical CO2 extraction process makes part of the chlorophyll decompose, and the chlorophyll content is very small, so its photo-oxidative stability is strong.

The peroxide value mainly measures the content of hydroperoxide, and hydroperoxide is easy to decompose, so the peroxide value is often used to measure the initial oxidation degree of oil, and cannot fully reflect the oil with a deeper degree of oxidation. However, hydroperoxides have an unpleasant taste after decomposing into small molecules such as aldehydes, ketones, acids, etc., which can be measured by sensory evaluation. In this way, the oxidation stability of walnut oil can be truly reflected through the determination of peroxide value and sensory evaluation.

evening primrose pressed oil vs. co2 extract

| Evening primrose-pressed oil | Evening primrose CO2 extract | |

| INCI name | Oenothera biennis oil | Oenothera biennis seed extract |

| Major Components | ||

| Density (20 oC) g/cm3 | 0.925 | 0.910-0.940 |

| Refractive index (20 oC) | 1.4759 | 1.4760-1.4810 |

| Sap. Value mg KOH/g | 193 | 193 |

| Unsaponifiables | 1.7% | 3.5% |

| Fatty acid composition | ||

| Palmitic acid (C16:0) | 6.3% | 6.1% |

| Stearic acid (C18:0) | 2.2% | 1.9% |

| Oleic acid (C18:1) | 7.2% | 7.1% |

| Linoleic acid (C18:2) | 73.3% | 74.5% |

| Gamma Linolenic acid (C18:3) | 8.9% | 9.7% |

| Palmitoleic acid (C16:1) | Trace | Trace |

| Vaccenic acid (C18:1) | Trace | Trace |

| Alpha-linolenic acid (C18:3) | Trace | Trace |

| Arachidic acid | Trace | Trace |

| Unsaponifiables | ||

| Sterols | 0.96% | 0.94% |

| Tocopherols | 770 ppm | 300 ppm |

cardamon essential oil vs. co2 extract

| Cardamon EO | Cardamon CO2 extract | |

| INCI name | Elettaria cardamomum seed oil | Elettaria cardamomum fruit extract |

| Major components | ||

| Terpinyl acetate | 40.44% | 50.0% |

| 1,8-cineole (Eucalyptol) | 29.90% | 25.40% |

| Linalyl acetate | 5.02% | 6.30% |

| Sabinene | 4.79% | 2.00% |

| Linalool | 3.20% | 3.30% |

| Limonene | 2.51% | 1.40% |

| Myrcene | 1.96% | 0.41% |

| Alpha terpineol | 1.79% | 2.20% |

| Alpha pinene | 1.61% | 0.68% |

| Geraniol | 1.11% | 0.72% |

| Neral | 0.35% | 0.44% |

| Geranial | 0.47% | 0.32% |

Since 1989. Experts in CO2 Extraction Machine.

Now, you also have a professional 30+ Supercritical Fluid Extraction lab team.

High-Quality CO2 Essential Oil Extraction Equipment for any vegetable oil CO2 Extraction Process.

Hot Sale small (1oz) up to Industrial Supercritical CO2 Extraction Machine Online from China.