Vanilla is one of the most popular flavors in the world, with a wide range of applications in the food, beverage, and cosmetic industries. The demand for vanilla has increased significantly in recent years, leading to concerns about its sustainability and the need to find innovative methods for its production. Conventionally, vanilla is obtained through labor-intensive and time-consuming processes, which can have negative impacts on the environment and the livelihoods of vanilla farmers. Supercritical CO2 (SC-CO2) extraction has emerged as a promising alternative for the sustainable and effective extraction of vanilla compounds from orchid pods. This article will discuss the principles, procedures, and advantages of SC-CO2 extraction for vanilla orchid pods, with a focus on its potential applications and sustainability.

Principles of SC-CO2 Extraction

Supercritical CO2 extraction is an extraction technique that utilizes CO2 as a solvent under high pressure and temperature conditions. SC-CO2 exhibits unique properties that make it an ideal solvent for extraction processes, such as its high solubility, low viscosity, and non-toxic nature. In the case of vanilla extraction, SC-CO2 is used to extract the compounds responsible for vanilla flavor and aroma from the orchid pods. The SC-CO2 extracts the compounds from the pods and then separates the mixture to obtain the desired vanilla extract fraction.

Procedures of SC-CO2 Extraction for Vanilla Orchid Pods

The SC-CO2 extraction of vanilla orchid pods involves several critical steps, as summarized in Table 1 below.

Table 1: Summary of SC-CO2 extraction procedures for vanilla orchid pods

| Step | Procedure |

|---|---|

| 1 | Drying and milling of vanilla orchid pods |

| 2 | Loading the milled pods into the extraction vessel |

| 3 | Pumping CO2 into the extraction vessel to achieve the desired pressure and temperature |

| 4 | Extracting the vanilla compounds from the pods |

| 5 | Separating the vanilla compound and CO2 mixture to obtain the desired vanilla extract fraction |

| 6 | Collecting, analyzing, and characterizing the extracted vanilla extract |

Advantages of SC-CO2 Extraction for Vanilla Orchid Pods

SC-CO2 extraction offers several advantages over traditional methods for the extraction of vanilla compounds from orchid pods. Firstly, it is a precise and efficient method that yields a high-quality extract with excellent sensory properties. Secondly, it utilizes a non-toxic, environmentally friendly, and reusable solvent that reduces the risk of environmental pollution and health hazards. Thirdly, it is a continuous process that is easy to scale up for large-scale production. Finally, it reduces the amount of vanilla pods required for extraction, which helps to conserve natural resources and reduce costs.

Applications of Vanilla Extract

Vanilla extract has many applications in the food, beverage, and cosmetic industries. In the food industry, vanilla extract is used as a flavoring agent for various products, such as bakery goods, ice cream, and confectionery. In the beverage industry, vanilla extract is used as a flavoring agent for soft drinks, coffee, and tea. In the cosmetics industry, vanilla extract is used as a fragrance and flavoring agent for various products, such as perfumes, lotions, and soaps.

Sustainability of SC-CO2 Extraction for Vanilla Orchid Pods

SC-CO2 extraction is a sustainable method for the extraction of vanilla compounds from orchid pods. Firstly, it utilizes a non-toxic, environmentally friendly, and reusable solvent that reduces the risk of environmental pollution and health hazards associated with traditional extraction methods. Secondly, it reduces the amount of vanilla pods required for extraction, which helps to conserve natural resources and reduce the carbon footprint associated with vanilla production. Finally, it is an efficient and continuous process that reduces the energy consumption and cost associated with vanilla production.

Summary

In conclusion, the use of SC-CO2 extraction for the extraction of vanilla compounds from orchid pods offers several key advantages, including high-quality extract, environmentally friendly and sustainable process, and cost savings. This method has become increasingly popular in recent years due to its efficiency, precision, and eco-friendliness. Vanilla extract has many potential applications in various industries, and the use of sustainable extraction methods such as SC-CO2 extraction will be increasingly important for meeting the increasing demand for vanilla and other natural products.

Advantages of SC-CO2 Extraction for Vanilla Orchid Pods

SC-CO2 extraction offers several advantages for the extraction of vanilla compounds from orchid pods, as listed below:

- High quality extract with excellent sensory properties

- Non-toxic, environmentally friendly, and reusable solvent

- Precise and efficient method that is easy to scale up for large-scale production

- Continuous process that reduces energy consumption and costs

- Potential applications in food, beverage, and cosmetic

- industries

- 6. Sustainable method that conserves natural resources and reduces carbon footprint

Vanilla is a precious commodity that is in high demand all over the world. However, its traditional extraction methods are labor-intensive, time-consuming, and unsustainable. Supercritical CO2 extraction offers a modern and innovative method for the extraction of vanilla compounds from orchid pods. It is a sustainable, precise, and efficient process that yields high-quality vanilla extract with excellent sensory properties. With the continued growth of the food, beverage, and cosmetic industries, the use of sustainable extraction methods such as SC-CO2 extraction will be increasingly important for meeting the increasing demand for vanilla and other natural products.

CO2 Extraction Process for Vanilla Essential Oil

- Pulverization degree: 80 mesh

- Extraction pressure: 20 MPa

- Extraction temperature: 45°C

- Separation pressure: 6 MPa

- Separation temperature: 60°C

- Extraction time: 100 min

CO2 EXTRACTION METHOD OF VANILLA OIL

About the CO2 extraction experiment

This is a small experiment of CO2 extraction of vanilla essential oils. The CO2 extraction equipment used was: Supercritical CO2 extraction machine L-05

Pulverize

- Grind vanilla orchid pods into powder, about 85g.

- Pulverization degree: 80 mesh

Pulverize size effect in vanilla oil CO2 extraction process

The pulverized size of the vanilla raw material has a significant effect on the extraction process and efficiency.

Vanilla essential oil is generally stored in vanilla plant cells. If it is not crushed, the resistance of the cell wall will slow down the extraction speed and reduce the extraction amount. The CO2 fluid diffuses into the vanilla tissue as soon as possible, thereby improving the extraction rate. Too fine particle size will aggravate the thermal effect of the SCF-solid interface and block the mesh. Although the damage to the plant cell wall is more thorough at this time, it increases the accumulation of vanilla raw materials. The density and permeability become poor, so that CO2 only passes through the material layer along the line with low resistance, forming many pinholes, making the extraction significantly uneven. At the same time, it is also possible that under the action of pressure, it will quickly form dense lumps, which will affect the yield of essential oils at light level, and make extraction impossible due to the sudden increase of pressure difference before and after the extractor.

co2 extraction process step one

- Low pressure (14MPa) extraction for 25 minutes

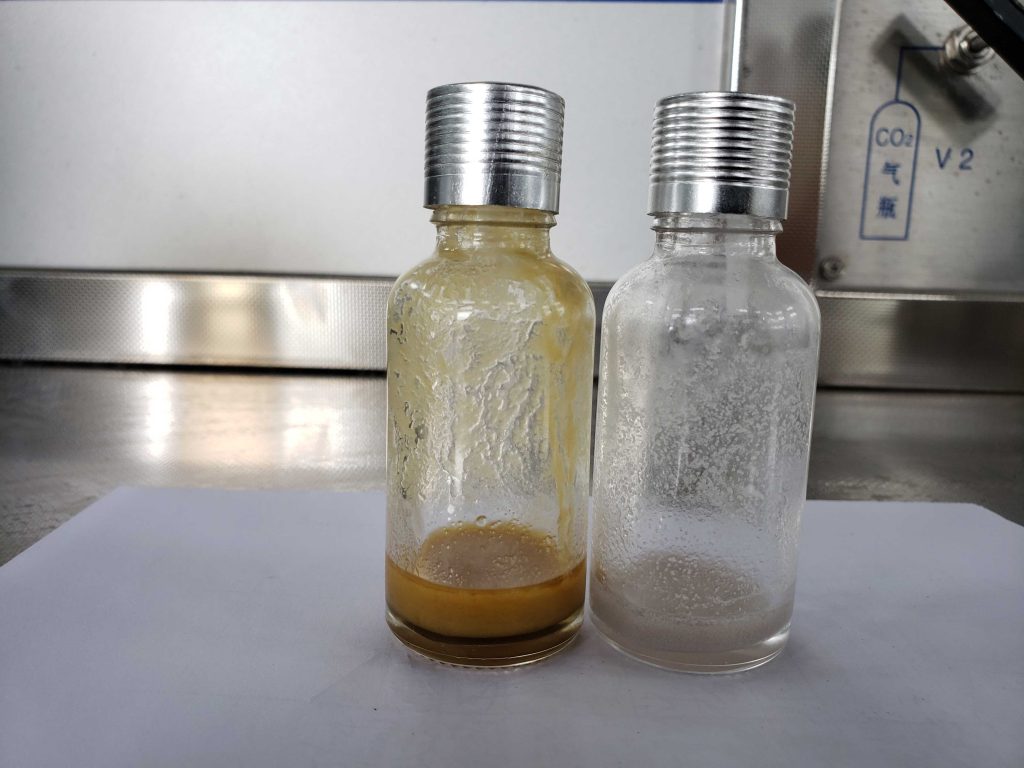

- Separate the kettle to obtain a light yellow liquid

- Nothing obtained from the second separation kettle

co2 extraction process step two

- Medium pressure (20MPa) extraction for 20 minutes

- Separate kettle 1 to obtain dark full-spectrum liquid

- Separate kettle 2 to obtain a small amount of white liquid

- High pressure (28MPa) extraction for 20 minutes

- Separating kettle 1 and separating kettle 2 did not get any material

SUM UP

Final extract

There is residue in the nozzle of the separation kettle, and there is also residue in the internal pipeline

Extraction residue

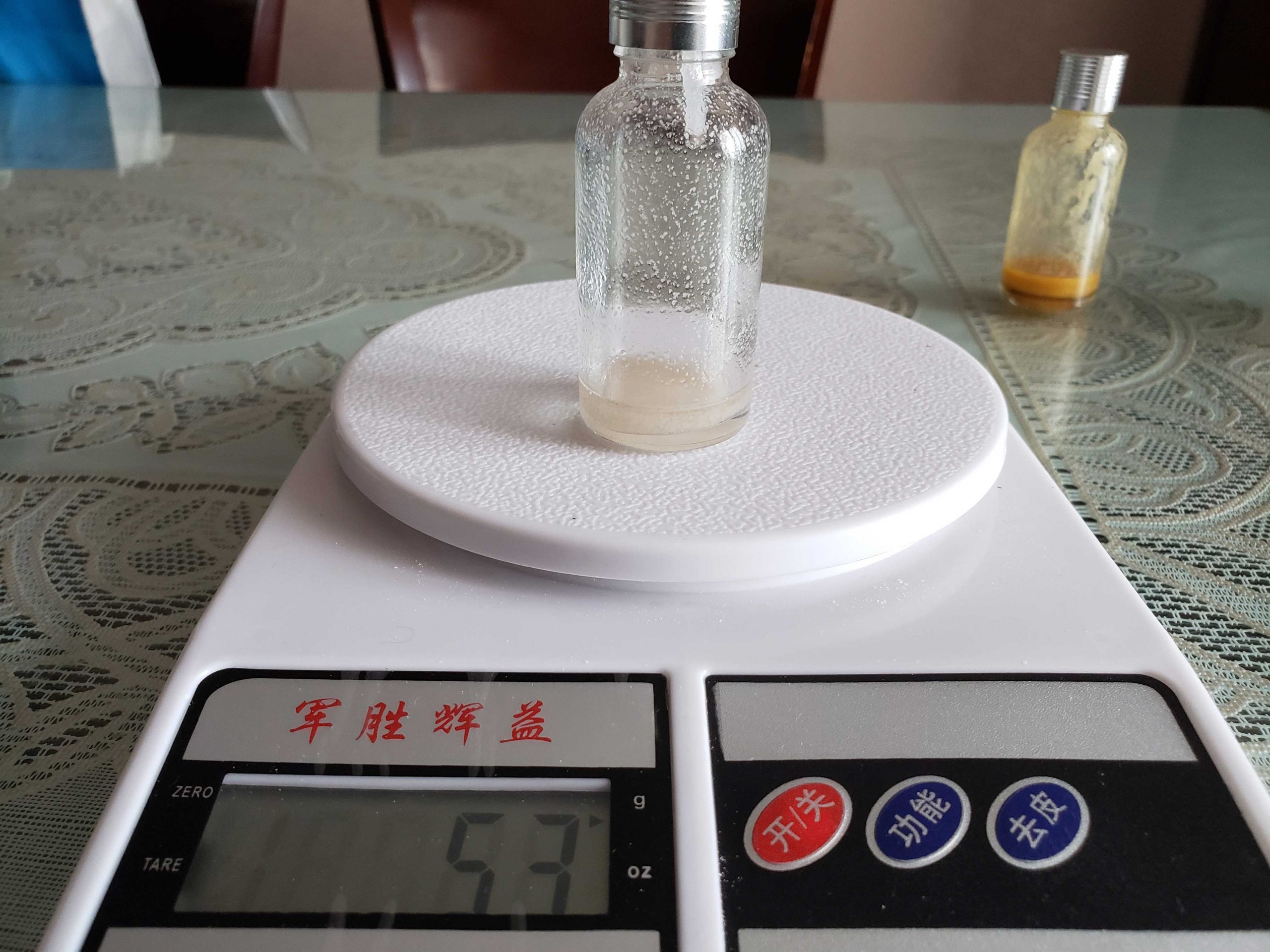

Name Crushed vanilla Separate the extract of kettle one Separate the extract of kettle two-weight About 85g 5g 3g Total: 8g.

Notes:

The extract was 93 grams, which was only 85 grams after crushing. The final separation tank 1 obtained only 5 grams. Because there are too few extraction materials available for testing, the test data may be inaccurate (the machine nozzle and pipeline will have extraction liquid residue, weighing, and measurement errors), and the optimization test volume is recommended 2 kg of raw materials.

Our company has done Hainan vanilla extraction for a research in Hainan Province, China, and the final separation-extraction rate is about 5-8%;

After testing, we agreed that the raw material extract in this test has a higher yield than Hainan’s vanilla

Analysis of CO2 Extraction Process of Vanilla Essential Oil

Raw Pulverize

The extraction efficiency of vanilla tissue essential oils essentially depends on the contact between the extraction solvent and vanilla cell membrane phospholipids and cytoplasm, the mutual solubility efficiency, and the mass transfer rate of essential oils diffused through the solvent system through the cell wall.

To improve the extraction rate of vanilla essential oil, the key is to destroy the continuous water film at the interface between cells and organelles, so that the extraction solvent and vanilla essential oil can be effectively contacted and dissolved in each other.

In the process of supercritical CO2 extraction of vanilla essential oil, when there is still a small amount of water in the dry vanilla powder material, the supercritical CO2 fluid will bring the water to the vicinity of the outlet of the extraction tank, so that the vanilla powder will quickly freeze under high pressure. block, affecting the permeability of supercritical CO2 fluid and the extraction process.

Although the supercritical CO2 fluid has better mass transfer performance and faster diffusion rate, since the controlling step for the final transfer of the solute in the solid to the supercritical CO2 fluid phase is the diffusion rate of the solute in the solid, which depends on the solute The magnitude of the diffusion coefficient in a solid and the size of the solid.

The effect of extraction pressure on the CO2 extraction process

In the supercritical CO2 extraction process of vanilla essential oil, when the pressure is between 10MPa and 60MPa, the yield is relatively stable, but the content of non-volatile components (such as wax) increases with the increase of pressure. Increased loss of components (oil), and CO2 extracts at high pressures (greater than 300bar) will be paste-like.

Therefore, choosing the right extraction pressure is especially important in the vanilla essential oil CO2 extraction process.

The effect of extraction temperature on the CO2 extraction process

The solubility of a vanilla essential oil varies with temperature.

With the increase of temperature, the thermal motion speed of molecules increases, the probability of mutual collision increases, and the probability of association increases;

The increase in temperature increases the volatility of the solute and increases the diffusion coefficient;

As the temperature increases, the density of CO2 decreases, and the ability to carry substances decreases.

When the temperature increased from 40 ℃ to 60 ℃, the main components, especially the volatile components of vanilla, were significantly reduced due to the high-temperature flash volatilization under the carry of CO2, and the extract of high-temperature extraction operation contained more water.

The high-temperature process may increase the volatility of the water, but it is not conducive to the extraction of terpenes (such as vanilla odor) and oxygenated derivatives. In addition, if the extract is a heat-sensitive active ingredient, a lower temperature extraction should be considered.

In fact, the increase of extraction rate under high-density CO2 is mainly due to the increase of surface wax and other undesired components.

Adjusting the dissolving ability and selectivity of supercritical CO2 fluid is beneficial to overcoming the technical difficulty of extracting non-volatile components entrained in one-time extraction and separation. Under the condition of CO2 density lower than 0.6g/cm3, it is possible to extract as many essential oil components as possible, and other non-volatile components except surface wax will not be extracted.

When the CO2 density is too high, such as higher than 0.85g/cm3, not only the extraction rate decreases, but also the technical difficulty is caused by the increase of the extraction amount of waxes and triglycerides.

Therefore, it is important to adjust the temperature and pressure in the CO2 extraction process of vanilla essential oil.

In the test three months later, we also verified the truth of this CO2 extraction process.