Soy lecithin is a commonly used emulsifier in food processing due to its ability to disperse fats and oils in water. However, it contains residual oil that can negatively affect the quality of the end products. The supercritical CO2 deoiling process is an effective method for removing residual oil from soy lecithin. This article will discuss the process and its advantages.

The Supercritical CO2 Deoiling Process

The supercritical CO2 deoiling process involves using supercritical carbon dioxide as a solvent to remove the residual oil from soy lecithin. Supercritical CO2 is a unique solvent that has a low surface tension and high diffusivity that makes it effective in penetrating into porous materials such as soy lecithin.

The process starts by loading the soy lecithin into a vessel and applying high pressure and temperature to convert the CO2 into a supercritical state. The supercritical CO2 is then passed through the soy lecithin, dissolving the residual oil. The solvent-oil mixture is then separated and depressurized to remove the CO2, leaving behind the deoiled soy lecithin.

Advantages of the Process

The supercritical CO2 deoiling process of soy lecithin has several advantages over other deoiling methods. Firstly, it is a clean and efficient process that does not involve the use of harmful solvents or chemicals. This makes it an environmentally friendly option.

Secondly, the process is selective and does not affect the quality or functionality of the soy lecithin. It only removes the residual oil, leaving behind a pure and high-quality product.

Thirdly, the process is fast and cost-effective. It takes only a few hours to complete, and the equipment required is relatively simple and inexpensive.

Comparison with Other Deoiling Methods

There are several other deoiling methods that are commonly used in the industry, including solvent extraction, enzymatic hydrolysis, and membrane separation.

Solvent extraction involves using organic solvents to extract the oil from soy lecithin. Although it is a common method, it is not very efficient and can leave behind harmful residues.

Enzymatic hydrolysis involves using enzymes to break down the residual oil in soy lecithin. It is a selective method, but it is time-consuming and expensive.

Membrane separation involves using selective membranes to separate the oil from soy lecithin. It is a clean and selective method, but it can be costly and requires specialized equipment.

In comparison, the supercritical CO2 deoiling process of soy lecithin is a clean, efficient, and selective method that is also cost-effective. Therefore, it is a preferred option for many food processing companies.

Summary

The supercritical CO2 deoiling process of soy lecithin is an effective method for removing residual oil from soy lecithin. It is a clean, efficient, and selective method that does not affect the quality or functionality of the soy lecithin. It is also a cost-effective option and is preferred over other deoiling methods by many food processing companies. By implementing this process, the quality and safety of food products can be improved while also reducing the environmental impact of food processing.

Advantages of the supercritical CO2 deoiling process of soy lecithin

- Clean and environmentally friendly

- Selective and does not affect the quality or functionality of the soy lecithin

- Fast and cost-effective

Comparison of Different Deoiling Methods for Soy Lecithin

| Deoiling Method | Advantages | Disadvantages |

|---|---|---|

| Supercritical CO2 Deoiling | Clean, efficient, selective, cost-effective | Equipment necessary |

| Solvent extraction | Common | Not very efficient, harmful residues |

| Enzymatic hydrolysis | Selective | Time-consuming, expensive |

| Membrane separation | Clean, selective | Costly, specialized equipment |

Possible additional paragraph to include:

Applications of Deoiled Soy Lecithin

Deoiled soy lecithin has many applications in the food industry due to its functionality and emulsifying properties. It is commonly used in the production of baked goods, confectionery, dairy products, and beverages, among others. For instance, it can be used as a releasing agent in baking or a stabilizer in ice cream. Deoiled soy lecithin can also be used in non-food applications, such as cosmetics, pharmaceuticals, and animal feed. As a result, the demand for deoiled soy lecithin is increasing, and the supercritical CO2 deoiling process can help meet that demand.

Overall, the supercritical CO2 deoiling process of soy lecithin is a promising technology for the food industry. It can help improve the quality and safety of food products while reducing the environmental impact of food processing. By including a list and a table, this article presents the advantages of the process and its comparison with other deoiling methods in a clear and concise manner. Furthermore, the potential applications of deoiled soy lecithin demonstrate the versatility and importance of this product in various industries.

Lecithin

Phospholipids are the general term for lipids containing phosphate roots.

The main components are phosphatidylcholine (lecithin), phosphatidylethanolamine (cephalin), phosphatidylinositol (inositol phospholipid), phosphatidic acid and phosphatidylserine.

Phospholipids are an indispensable component of animal and plant tissues and one of the basic materials of biofilms.

Biofilms are not only a protective barrier for cells, but also important structures for the synthesis, metabolism, and transportation of life substances. Phospholipids are guaranteed by their regular structure and properties. The normal structure and function of cells are the basic materials of life.

Phospholipids are also an important substance for the formation and transmission of nerve information in the brain, accounting for 30% of the brain’s weight. Phospholipids play an emulsifying role in the blood, which can effectively dissolve cholesterol and make it suspended in the blood, avoiding deposition and ensuring normal blood circulation. Phospholipids can dissolve and eliminate lipid peroxides in the body and activate cell functions.

Due to the above functional properties of phospholipids, phospholipids have the effects of regulating blood lipids, improving memory, and delaying aging. At the same time, it has no toxic side effects, and it is a kind of health medicine with great development prospects.

Experiment process

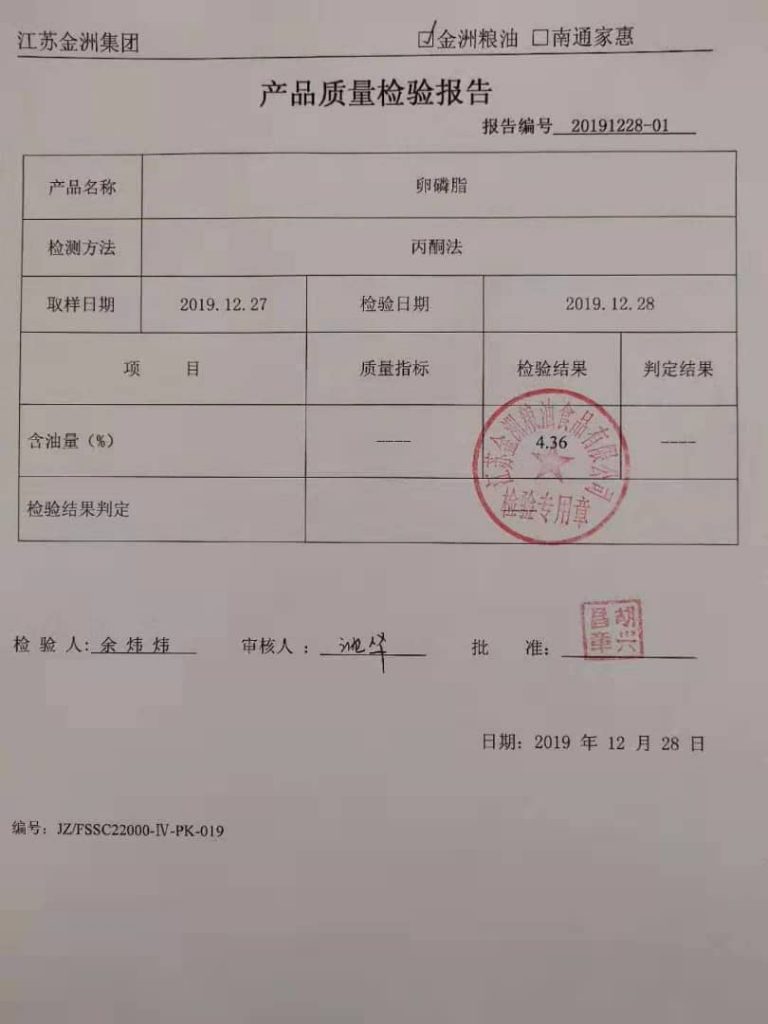

On December 25, 2019, we conducted a soy lecithin deoiling test at the request of an Indian company.

Raw material

Provided by an Indian company, containing 40-50% of liquid grease, in the form of ointment.

Lecithin deoiling test report

Summary

This is a preliminary one-time test. Our purpose is only to prove that the oil in lecithin can be removed by the SFE method.

In the test, we adopted a special process, which can make the test effect better.

Of course, in actual production, we need more tests to achieve the optimization deoiling effect.

Technically speaking, it can achieve 100% oil removal.

Process parameters

Extraction pressure: 21 MP

Extraction temperature: 45°C

Separation pressure: 6.5 MPa

Separation temperature: 60°C

Extraction time: 70 min

Other crafts: We use other special crafts